SAFETY MEASURES WHEN USING LPG IN INDUSTRY

06/01/2025

DATA Energy - A leading provider of investment, consulting, design, and installation services for industrial LPG gas systems nationwide. Learn about safety measures when using LPG in industry through the article below.

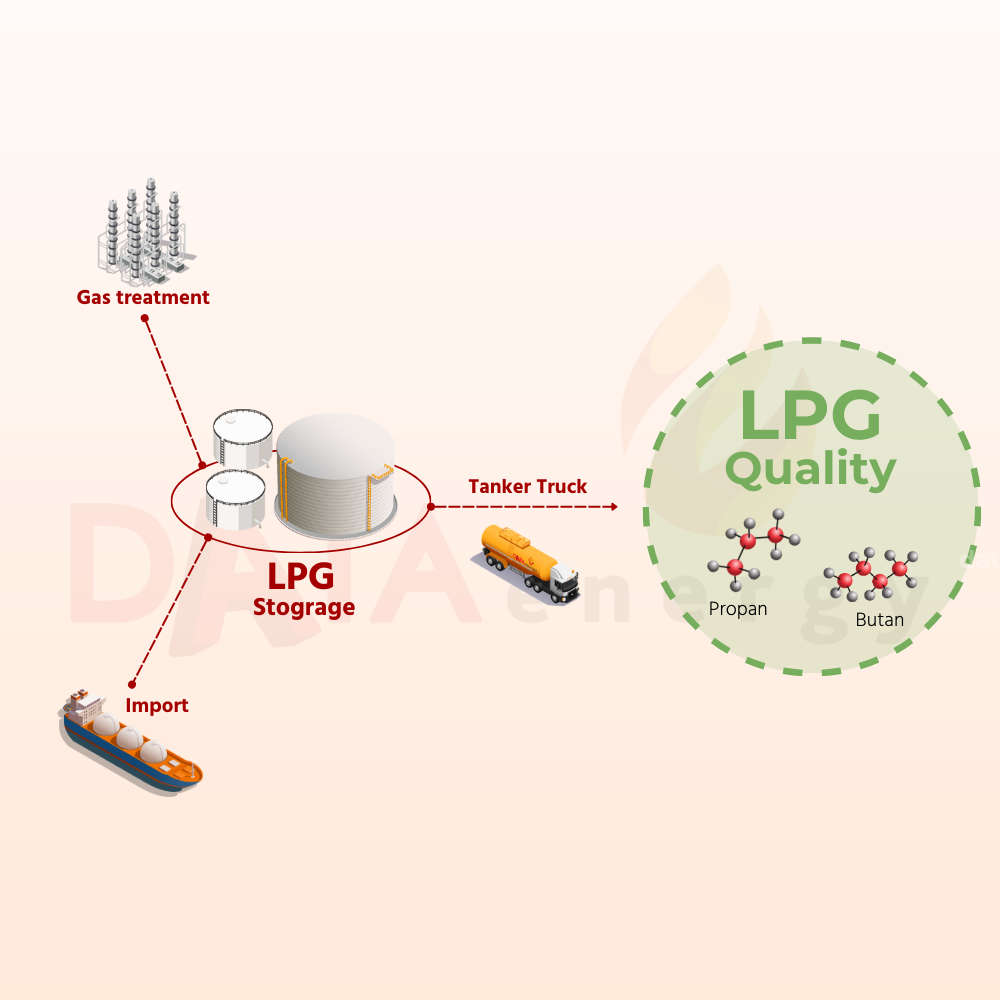

What is LPG? LPG stands for liquid petroleum gas, also known as liquefied petroleum gas. LPG is a mixture of hydrocarbon gases, primarily propane (C3H8) and butane (C4H10) in a 50/50 ratio. This mixture is compressed into a liquid state for storage under a certain pressure.

LPG in industry

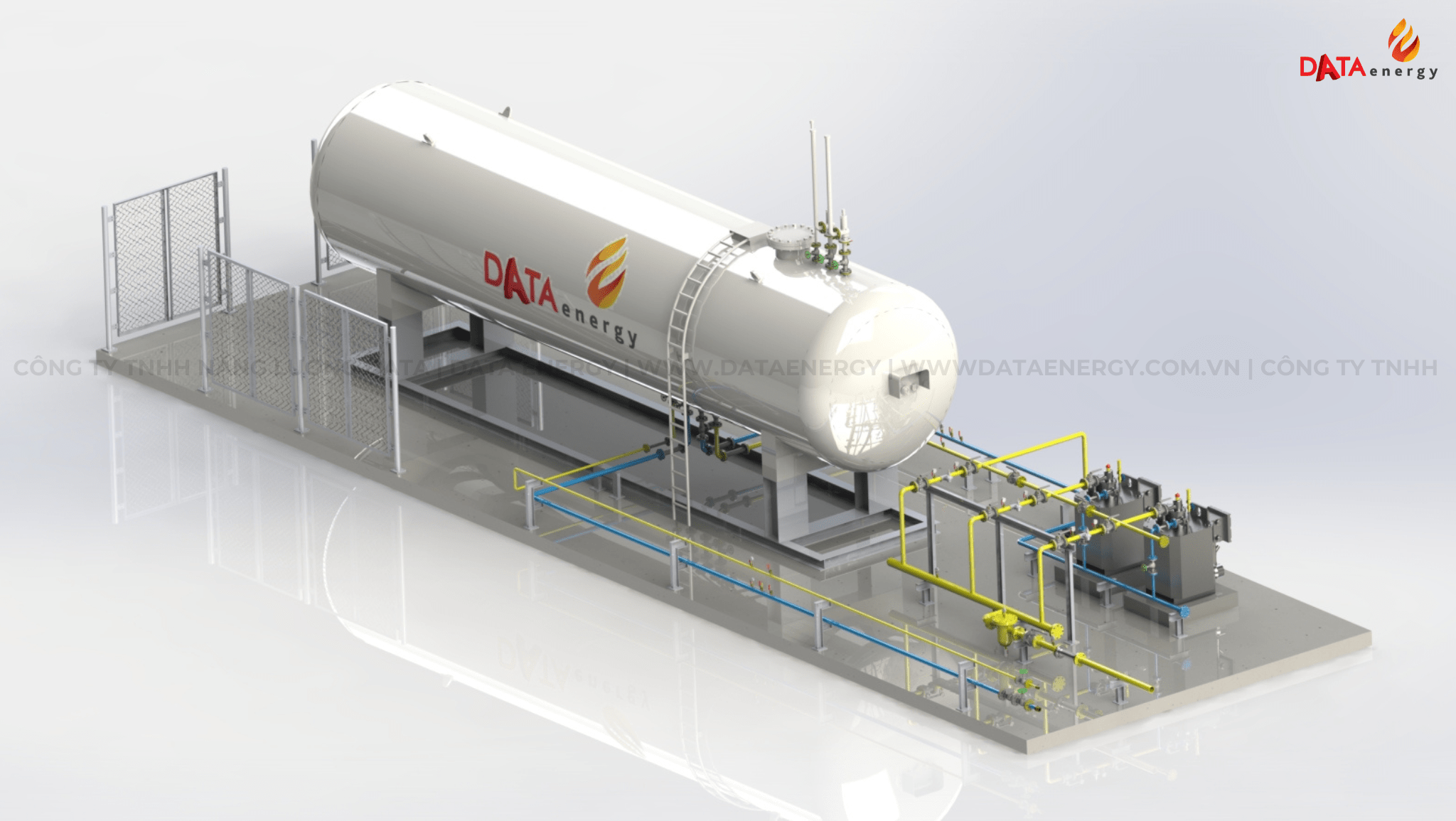

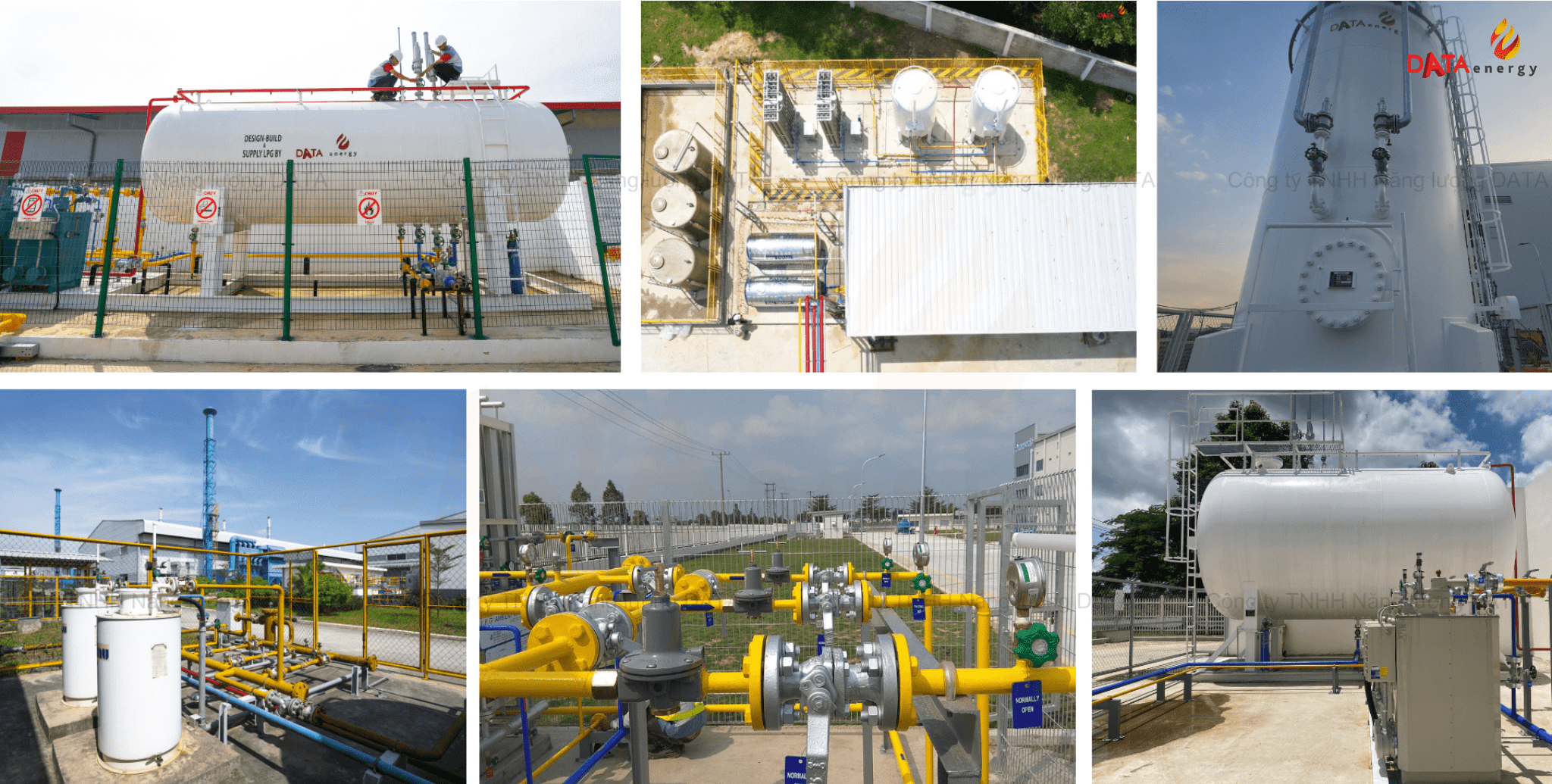

Liquefied petroleum gas (LPG) is used in industrial production activities such as drying, baking, welding, burning, and more. Additionally, LPG is also used as fuel in agricultural production, such as drying agricultural products, making fertilizers, and more. To use LPG in industry, the installation of an LPG station system is mandatory. Manufacturers can also rent this LPG station system from DATA Energy.

Industrial LPG Gas Station Video: https://www.youtube.com/watch?v=I8zyYtergiI&t=8s

SAFETY MEASURES WHEN USING LPG IN INDUSTRY

1. Safe LPG storage:

- Dedicated tanks: LPG must be stored in dedicated tanks, designed and manufactured according to international standards.

- Safe location: LPG tanks must be located in a well-ventilated area, avoiding direct sunlight and heat sources.

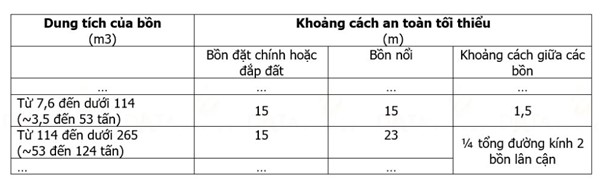

- Safe distance: Maintain a safe distance between the LPG tank and surrounding buildings and houses.

- Safety signs: Install clear, visible safety signs to warn of danger.

2. Installation and Inspection:

- Professional Installation: Always choose a professional LPG station installation company with expertise, experience, operating licenses, and complete safety and fire safety certifications.

Consider DATA Energy - One-stop Solution: https://www.youtube.com/watch?v=nNTfjgILGSw&t=3s

- Technical inspection: Before being put into operation, the LPG station system must be technically inspected by a competent unit. Inspection includes:

- Checking the tightness of the tank and pipeline.

- Checking the operation of safety devices such as safety valves and emergency shut-off valves.

- Checking the control and monitoring system.

- Periodic inspection: Regularly inspect the LPG station periodically according to the regulations of the manufacturer and the management agency. Inspection includes:

- Checking the tightness of the tank and pipeline.

- Checking the operation of safety devices.

- Checking the control and monitoring system.

- Checking the corrosion status of the tank and pipeline.

LPG System Maintenance Procedure Video: https://www.youtube.com/watch?v=FWRBe81DDoI

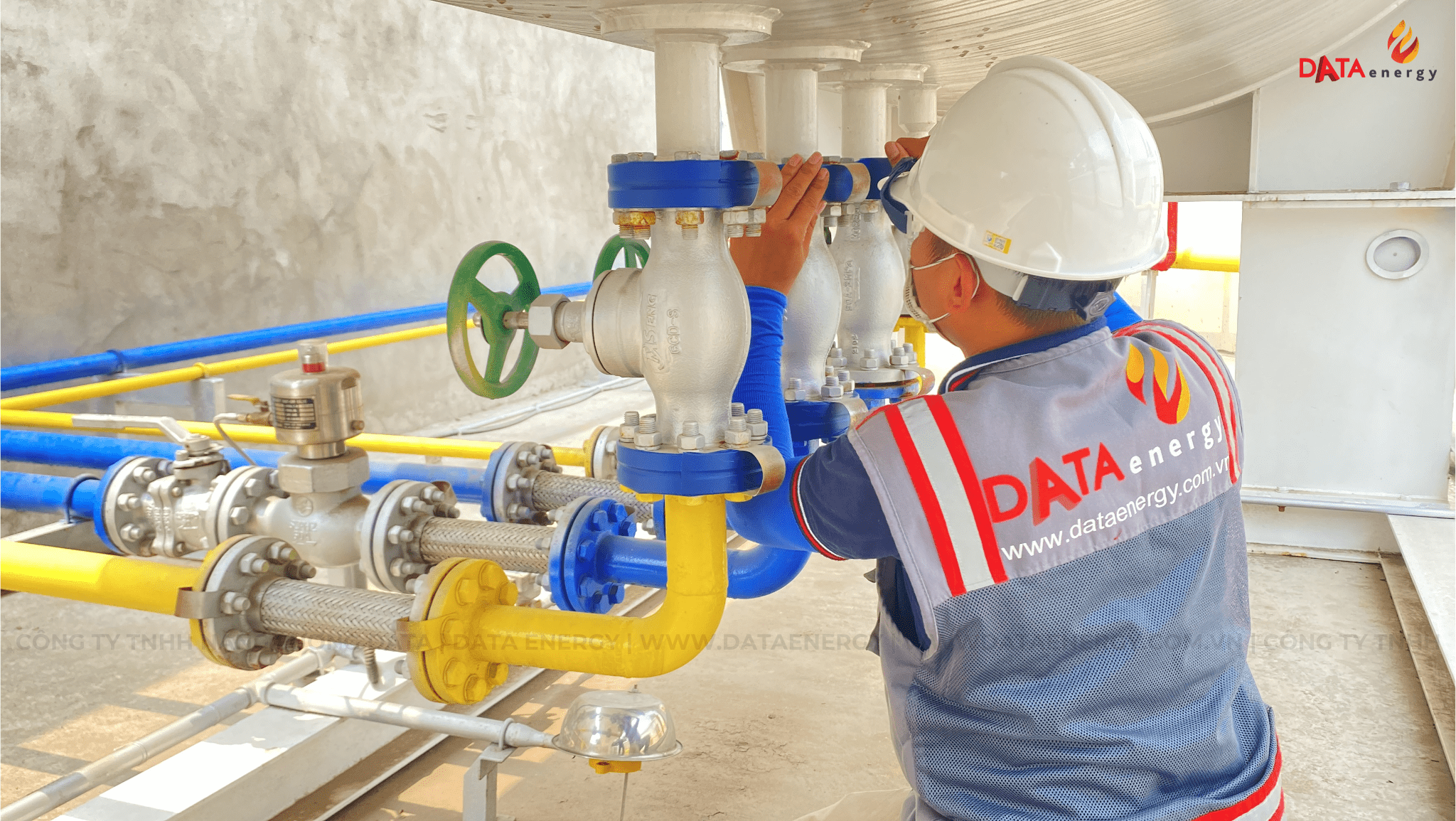

3. Operation and Maintenance:

- Adherence to safety regulations: Always strictly comply with labor safety regulations when operating the LPG station.

- Use of personal protective equipment: Always use appropriate personal protective equipment such as helmets, protective clothing, and masks when in contact with LPG.

- Equipment inspection before operation: Before operation, carefully inspect all equipment, pipelines, valves, and ensure normal operation.

- Regular inspection: Regularly check the amount of LPG in the tank, pressure in the pipeline, and temperature of the tank.

- Periodic maintenance: Perform periodic maintenance on equipment, pipelines, and valves according to the manufacturer's instructions.

- Safety training: Train employees on safety regulations, how to handle incidents, and use safety equipment.

4. Incident handling:

- Prepare a handling plan: Prepare handling plans for incidents, equip with complete fire fighting equipment.

- Employee training: Train employees on how to handle dangerous situations such as LPG leaks, fires, and explosions.

- Contacting authorities: In case of serious incidents, immediately contact authorities such as police and fire department for timely assistance.

- DATA Energy will provide operational instructions for the customer's technical staff to ensure the system operates safely and continuously, as well as monitor indicators and incident signals.

- DATA Energy also organizes maintenance of the industrial LPG gas system every 3 months and provides 24/7 support for incident handling.

Other:

DATA Energy will advise and supply gas to customers.

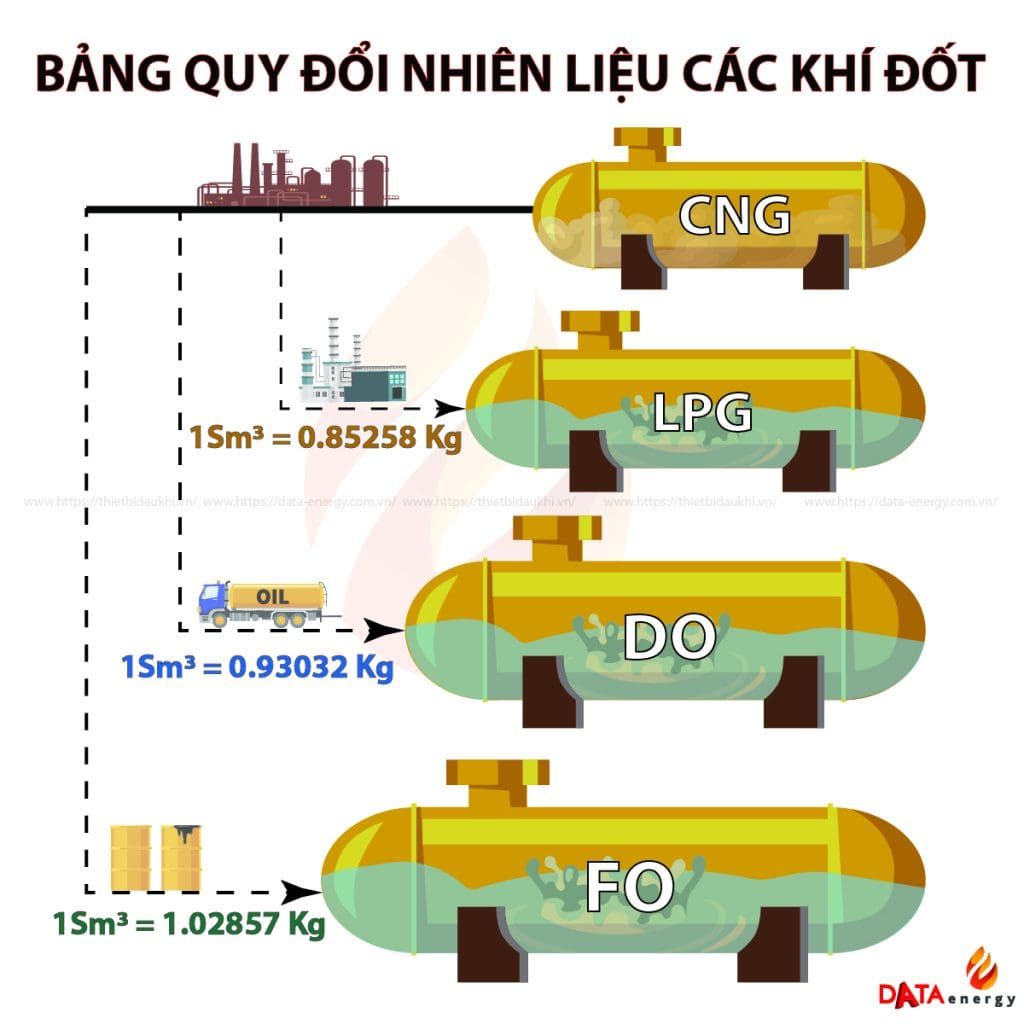

DATA Energy is also a consulting and gas conversion unit.

Contact us for detailed advice and quotation here.

See more:

What is LPG? Basic properties of liquefied petroleum gas

LPG industrial gas system installation process

Underground LPG tank installation

LPG station/ Industrial LPG (Gas) system

LPG/ Industrial Gas system design and installation unit

LPG - Liquefied petroleum gas supplier

TCVN 7441: 2004 Industrial LPG system design and installation standards

Internal sharing: Fire prevention safety

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.