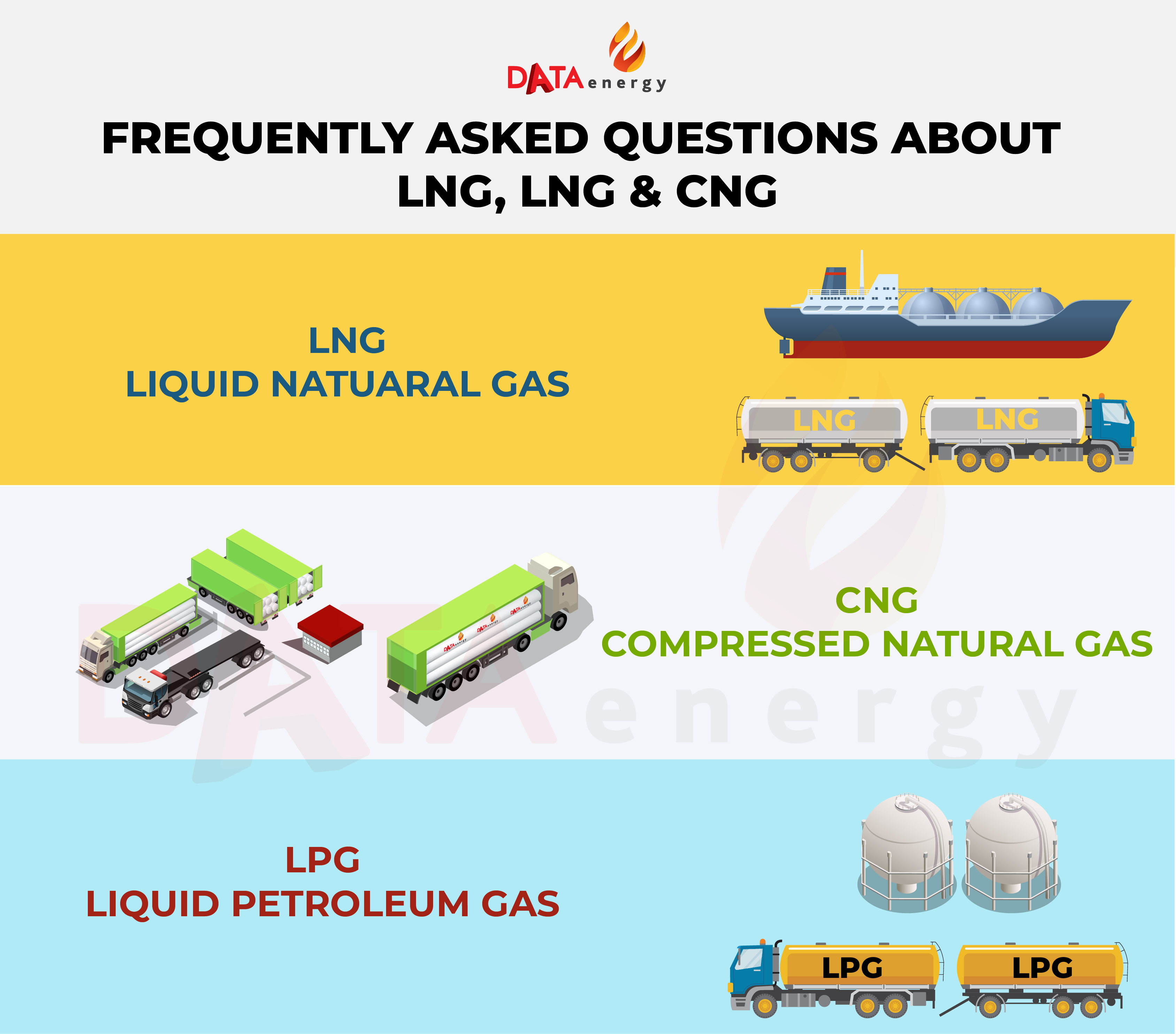

FREQUENTLY ASKED QUESTIONS ABOUT LNG, LNG & CNG

02/01/2025

LPG, LNG, CNG are commonly used gases today with superior properties andefficiency compared to traditional fuels. However, choosing which type of gas to suit the factory's needs to both ensure performance and optimize costs as possible still needs to be decided by many factors. Please follow the article below to compare the physical characteristics and technical requirements for the above 3 types of gases.

|

LPG - Liquefied Petroleum Gas |

LNG - Liquefied Natural Gas | CNG - Compressed Natural Gas | |

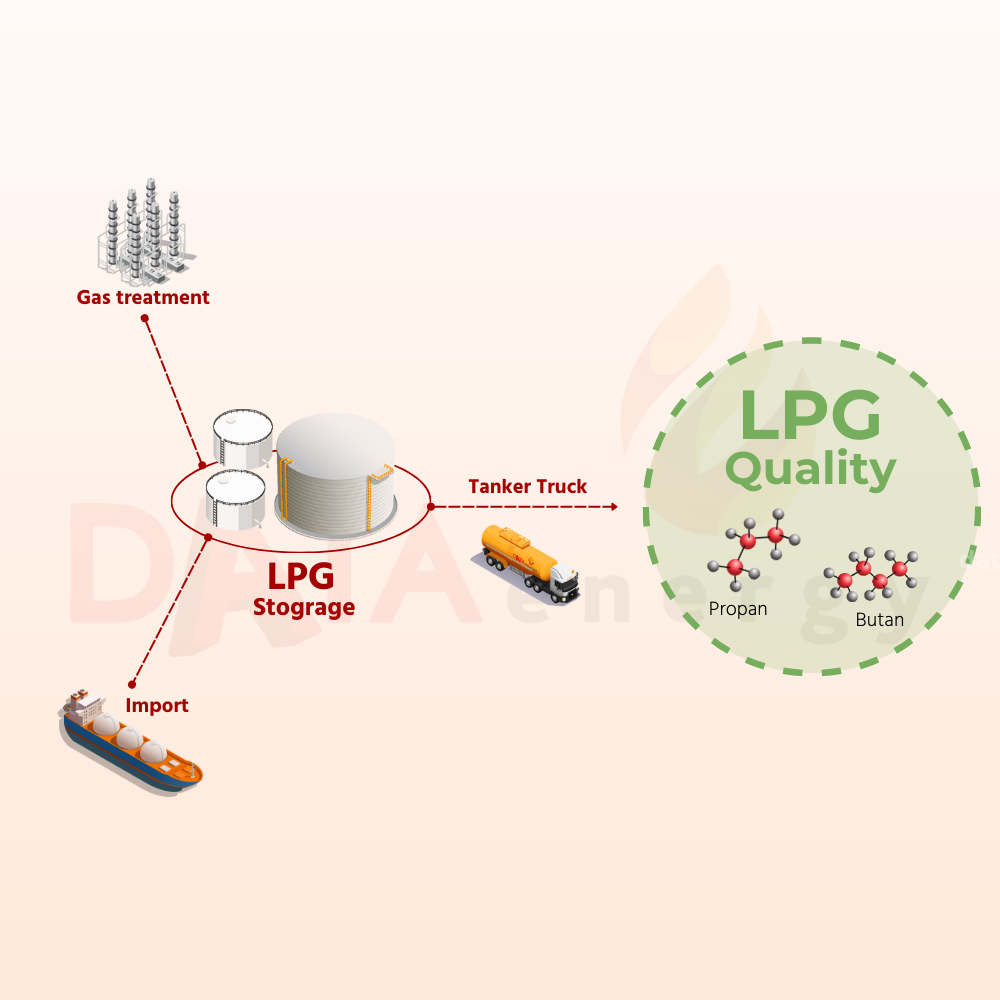

| Consisting Propane (C3H8) và Butane (C4H10) . LPG is stored by LPG tanks and transported by specialized trucks. | Consisting Methane (CH4), LNG is cooled at -162oC to convert to liquid. | Consisting largely of CH4 (Methane), it iss compressed at the high pressure 200 - 250 bar and transported by specialized trailers. | |

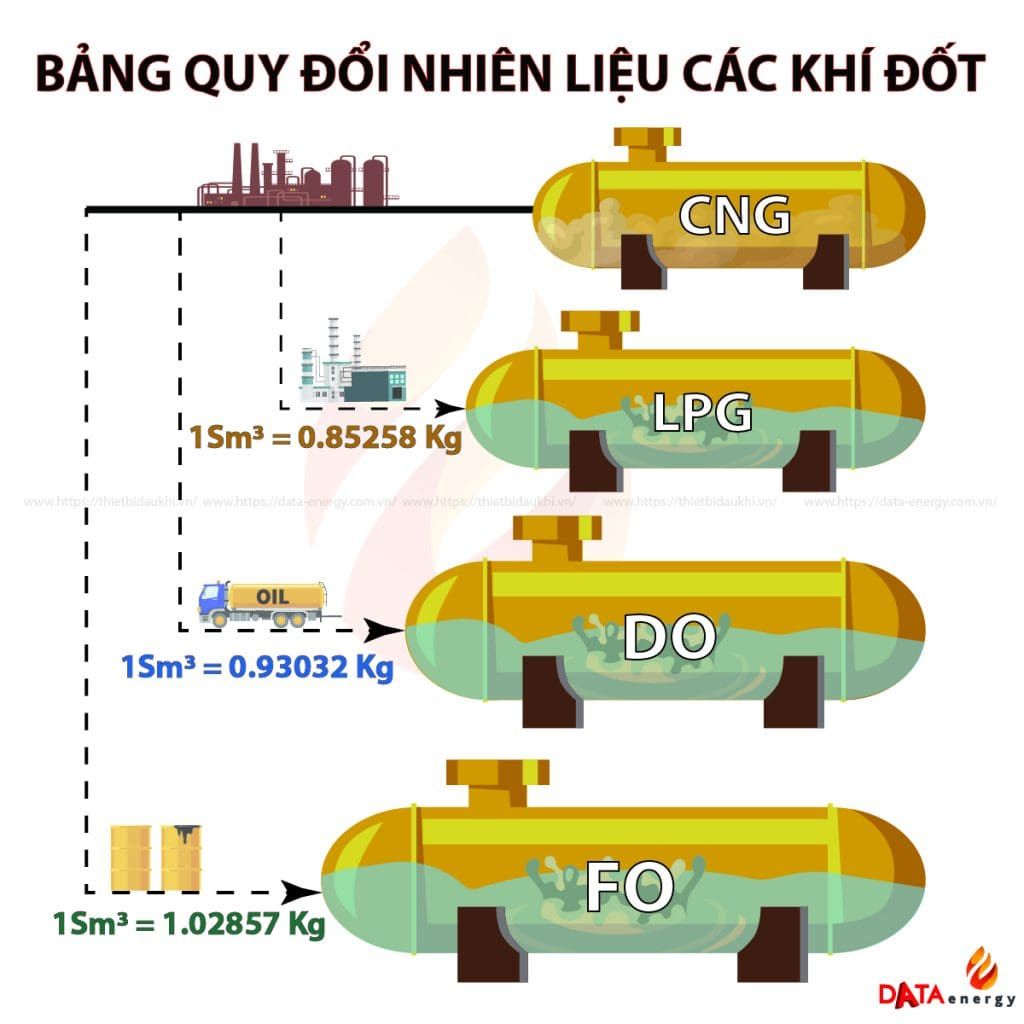

| Common Units | Tons, kg | Tons, mmBTU | Sm3, mmBTU |

| Gas Supply Source |

|

|

|

|

TECHNICAL SPECIFICATIONS |

|||

| Pressure |

|

|

|

| Square meters need to build a gas station |

10m x 5m = 50m2 To build 10MT tank system and relevant equipments with capacity of 200 kg/h. |

9m x 15m = 135m2 To build vertical LNG 30 m3 ~ 13.5 tons tank system and relevant equipments. |

15m x 17m = 255m2 To build 1500 Sm3/h CNG station with parking area for 3 40 - feet containers. |

| Delivery And Installation Time |

10 - 12 Weeks |

26 - 28 Weeks |

10 - 12 Weeks |

| Gas Equipment System Include | Tanks, regulator, vaporizers, safety valves, inlet pipes, piping system, groundimg system and measuring devices. | Tanks, regulator, vaporizers, safety valves, inlet pipes, piping system, groundimg system and measuring devices. |

PRU (2-level regulator, boilers, alarm devices, automatic shutdown valves, measuring devices) and grounding system & control room. |

| How does the system be operated and maintended? |

An operator is not necessary. The system is maintained by skilled technician quaterly. |

An operator is not necessary. The system is maintained by skilled technician quaterly. |

An operator is required 24/24 to operate and supervise the PRU system. The system is maintained by skilled technician quaterly. |

|

WHY SHOULD LPG, LNG, CNG BE USED? |

|||

|

|||

DATA Energy - A company specializing in providing reputable, quality LPG, CNG, and LNG gas with a stable supply source. Ensuring to bring customers the best quality products

Why should choose us?

- Guaranteed quality: DATA Energy committes to providing high quality gas with good efficiency.

Comprehensive service: At DATA, we not only provide gas but also provide consulting, design, installation, maintenance and servicing for LPG, CNG, LNG systems.

Safety is always the top priority for specific products such as LPG, CNG, LNG, we are committe to complying with all safety standards and industry regulations. - With a nationwide gas supply chain, we are committed to providing LPG gas in the right quantity and on time, ensuring that the plant's operation will continue without interruption.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.