LPG Quality – Performance and Safety in Use

27/02/2025

LPG (Liquefied Petroleum Gas) or liquefied petroleum gas is an important fuel source, widely used in manufacturing industries, especially heavy industries such as metallurgy, construction materials production, food production, etc.

Currently, LPG in Vietnam is using 2 sources: domestic production and import. The LPG supply chain extends from upstream, midstream to downstream. Through the process of exploitation, processing, transportation and filling before reaching the place of use.

Watch Gases Supply Chain in the Southest Video

This article will help you better understand the quality of LPG, its impact on performance, safety and how to choose standard LPG.

1. About LPG supply in Vietnam

In terms of business, PV GAS has supplied the market with nearly 2.5 million tons of LPG, of which nearly 1.6 million tons are produced and consumed domestically for civil, industrial and transportation purposes. (According to PVGAS 2023 annual report)

1.1. Domestic production accounts for about 50% of consumption output

|

Plant |

Sources |

|

Dung Quat Oil Refinery |

Mainly from Bach Ho, Dai Hung,… fields and imported sources |

|

Nghi Son Oil Refinery |

Imports crude oil entirely from Kuwait, Middle East |

|

Dinh Co Gas Processing Plant |

From Cuu Long and Nam Con Son basins |

|

Ca Mau Gas Processing Plant |

Mainly from Ca Mau field and other fields |

- Middle East (UAE, Qatar, Saudi Arabia)

- Korea, Japan

- Malaysia, Indonesia

- Russia, USA

2. What are the bases for assessing the quality of LPG?

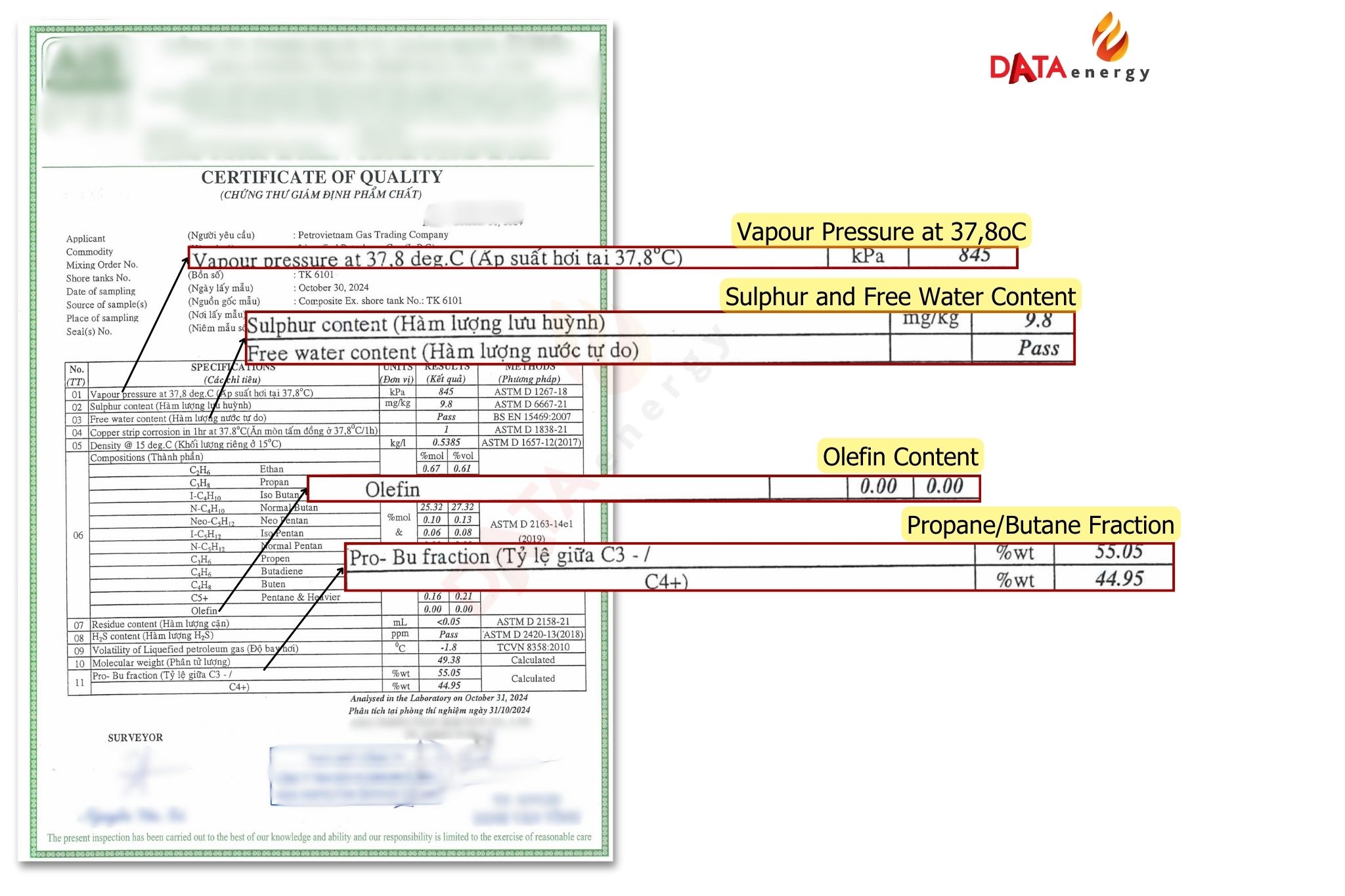

LPG quality is assessed based on the Certificate of Quality inspected by a third-party independent inspection unit. In which:

2.1. Origin of LPG - LPG extracted from a gas processing plant usually has a higher Propane ratio, LPG will have a higher calorific value and fewer impurities, suitable for industrial production needs.

LPG extracted from the oil refining process usually has a higher Butane ratio, LPG will be easier to liquefy and transport, suitable for civil use.

2.2. Main composition ratio of LPG - LPG is liquefied petroleum gas with a composition of 95% mixture of Butane and Propane. LPG usually has common Propane/Butane ratios such as: 50/50, 60/40, 70/30. Most of the LPG consumed on the market is commercial LPG with a Propane/Butane ratio of 50:50 (with a tolerance of 10%)

2.3. Additional components affecting the purity of LPG - In addition to Butane and Propane, LPG also contains other impurities such as sulfur, water, residue content and Olefin.

- H₂S and sulfur compounds can appear due to chemical reactions during the processing of petroleum and natural gas.

- Water (H₂O) can appear due to moisture from natural gas or crude oil that has not been completely removed during the refining process.

- Olefins are hydrocarbons with strong bonds and often have incomplete combustion, creating residue and soot.

Note that these impurity indexes must be within the allowable limits for the use of LPG to be safe.

2.4. LPG pressure - Pressure is determined by the composition of LPG. When using LPG, customers need to note that pressure always comes with temperature conditions, usually 37.8 degrees Celsius (100 degrees Fahrenheit) similar to outdoor LPG tanks.

3. Why is LPG quality important?

LPG quality directly affects the performance, durability of equipment and safety in production.

- Higher combustion efficiency – Pure LPG helps the combustion process to take place completely, generating more heat, reducing fuel consumption.

- Protecting equipment using LPG – Poor quality LPG can cause deposits on the burner, soot, reduce equipment life and affect the industrial combustion system.

- Ensuring production efficiency, products – Poor quality LPG gas sources can directly affect products of certain industries such as: precision molds, ceramics, electroplating, electronic components, etc. System maintenance can lead to line stoppage and cost of re-manufacturing the batch.

- Minimizing the risk of explosion – standard quality LPG helps maintain stable pressure, reducing the risk of leakage or explosion.

- Environmentally friendly – Clean LPG reduces emissions of toxic gases such as SO₂, NOₓ, protecting the health of users.

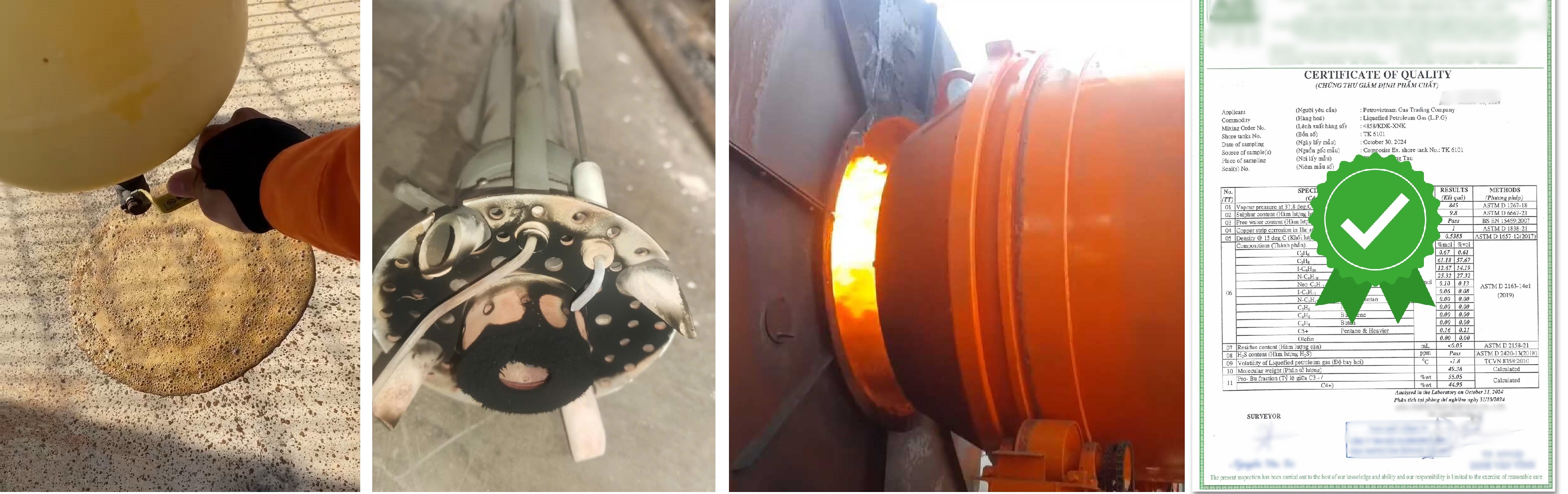

4. How to identify high quality LPG?

- Check the origin of LPG – You should choose reputable LPG suppliers, providing full LPG quality information and origin when delivering to the factory.

- Observe and check the storage system and burner – Sedimentation at the filter cluster and burner can be the cause of unstable LPG quality.

- Observe the flame color when burning – Pure LPG when burning has a steady blue flame, without black soot. If the flame is yellow or red, LPG may contain impurities.

Note on LPG quality assessment, the observed signs are for reference only and can have many different causes. Only authorized and specialized units have the function of checking and giving accurate conclusions.

5. Conclusion

To ensure the use of quality LPG that meets standards, choose a reputable supplier with quality inspection certificates, and good after-sales and maintenance services. Check the origin and safety standards when purchasing LPG to save costs, protect equipment and ensure safety during the production process.

Contact DATA Energy: 02862.757.005 or Ms. Oanh 0985.142.050 for advice on LPG quality and immediate quotes!

More Information:

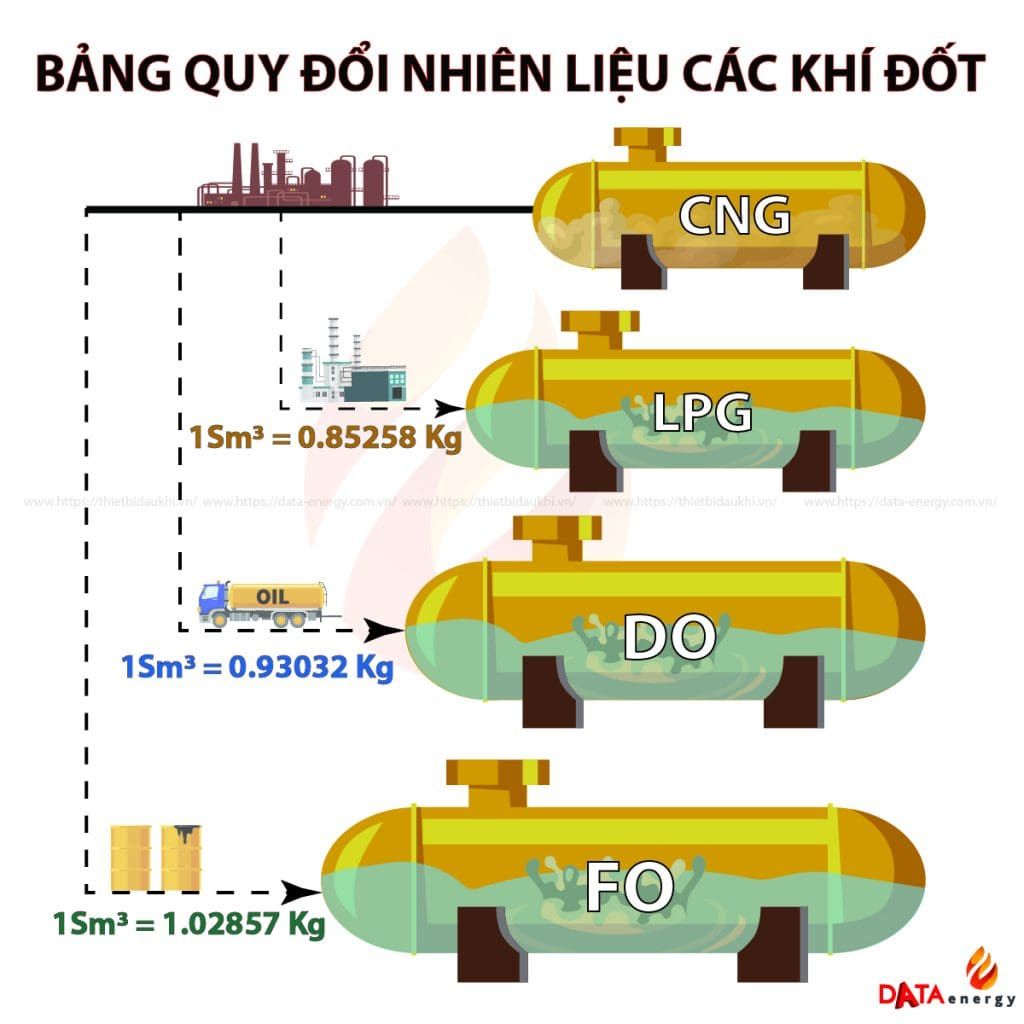

CALORIFIC VALUE OF DIFFERENT TYPES OF FUEL GASES

CO2 EMISSION COEFFICIENT FOR FUELS

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Consulting, designing, installing, and constructing industrial gas systems.

- Investing in gas systems for factories.

- Providing LPG, CNG, LNG.