LNG CONVERSION PROCESS

08/01/2025

With environmental and economic benefits, LNG is gradually becoming an important fuel source contributing to the sustainable energy development strategy of many countries in general and Vietnam in particular. In Vietnam, leading units are making efforts to promote the use of LNG faster and more popularly, so what is LNG? What are the steps in the conversion process to use LNG? Let's follow the article below.

LNG (liquefied natural gas) is a gas whose main component is CH4 (methane), colorless, odorless, cooled at -162oC to reduce the volume of natural gas by about 600 times, making it easier to store and transport, especially over long distances.

LNG CONVERSION PROCESS

Select the appropriate burner

- Assess the adjustment capability of the current burner to be compatible with LNG.

- In case of non-compliance, DATA Energy advises on selecting a specialized burner for LNG, CNG.

Prepare the area for station installation

- Ensure the minimum area for LNG station installation (the basic area for a 50m2 station is 200m2).

- Ensure the minimum safe distance from the factory or surrounding structures.

- Ensure sufficient space for LNG tanker movement and refueling.

Survey the station installation area

- Survey the station installation location to ensure compliance with fire safety standards, geological conditions, and infrastructure.

- Evaluate the area from the tank, gas pipeline to the burner and record the parameters.

Design and schedule

- Detailed design of LNG station, consulting customers on system capacity and selecting suitable equipment, optimizing layout for LNG system design.

- Coordinate with customers to establish construction permits and fire prevention and fighting approval.

- Develop detailed construction schedule, ensuring feasibility and efficiency.

Construction and installation of station according to design drawings

- Purchasing materials and importing equipment within 12 - 15 weeks.

- Installing station according to approved design.

- Connecting to customer's burner system.

Fire prevention and fighting acceptance and putting into use

- System inspection by a reputable third party.

- Trial operation to achieve design heat.

- Training operators/operational guidance for factory technicians.

- Inviting competent authorities to inspect fire prevention and fighting

Maintenance

- Perform periodic maintenance every 6 months.

- 24/7 technical support to ensure stable and safe system operation, promptly fix any problems that arise.

ADVANTAGES OF USING LNG

Reducing greenhouse gas emissions.

Switching to LNG significantly reduces CO2 and other emissions such as NOx and SOx, fine dust, contributing to cleaning the air and reducing the greenhouse effect. This is considered an important policy contributing to the implementation of Vietnam's commitment at Cop26 to reduce net emissions to zero by 2025.

High calorific value helps increase combustion efficiency.

LNG has a higher combustion efficiency than traditional fuels such as diesel or gasoline, helping to save costs and increase the efficiency of equipment and vehicles.

A safe fuel.

LNG is less likely to spontaneously ignite on hot surfaces, because it has a high auto-ignition temperature and a narrow flammability range (5% -15%). This means that if the concentration of LNG in the air fluctuates below 5% or above 15%, it will not burn. It is this high ignition temperature and limited ignition range that makes spontaneous ignition or accidental combustion very unlikely.

Diversifying energy sources.

The switch to LNG reduces dependence on traditional fuel sources, creating more diversity and stability in the energy supply.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

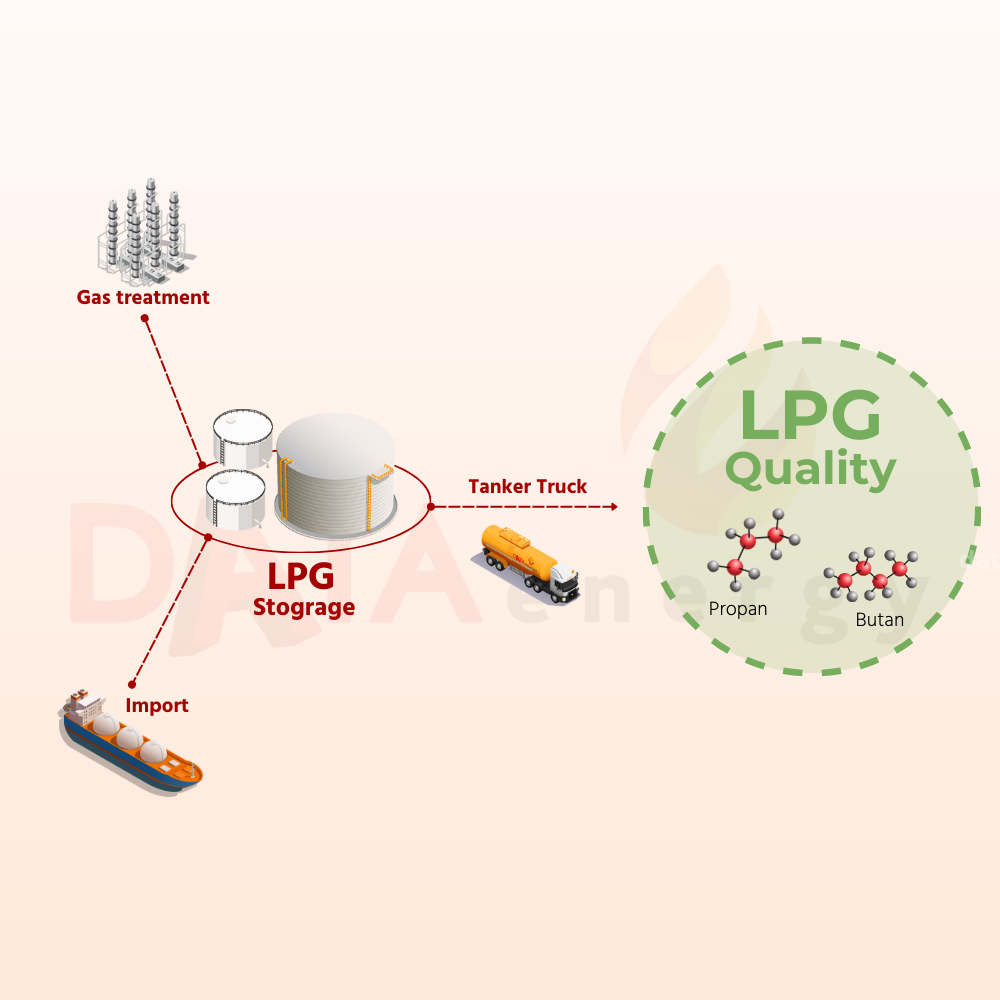

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.