LNG STATION - LNG SAFETY

06/01/2025

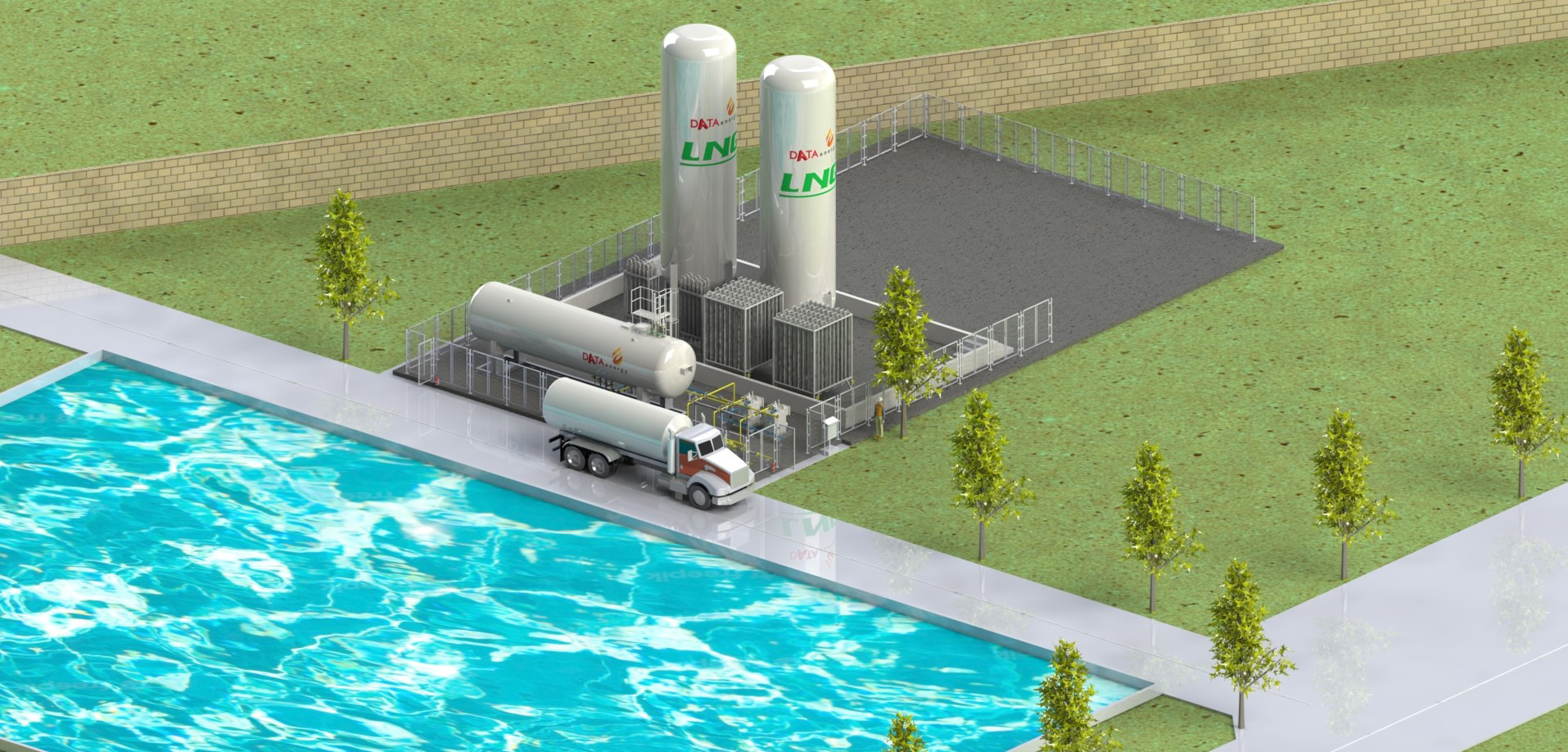

Learn about the LNG station, its equipment system and safety regulations in station installation through the content below.

Equipment in LNG station

LNG Tank: The tank is designed according to international standards, constructed of low temperature resistant steel, with insulation and reinforced tank shell with pre-stressed concrete. Design, fabrication and testing materials for steel tanks with operating pressure greater than 50kPA (500mbar). Tank capacities for industrial customers will typically have volumes of 10m3, 20m3, 30m3, 40m3, 50m3, 100m3, 150m3, 200m3 and a maximum of 400m3.

*The pressure measurement unit kPa, also known as Kilopascal, is a unit of pressure

LNG vaporizer: For LNG stations, natural vaporizers are usually used for vaporization. With an operating mechanism suitable for the temperature properties of LNG and an aluminum tape structure, the heat conduction process is better and faster. There is also the option of electric vaporization using hot water or steam, however the cost of investing and operating equipment for these methods is quite expensive.

Auxiliary devices (valves,...)

Pipe system

Electrical equipment

Measuring and warning equipment

Pressure reducing and measuring equipment

-min.png)

Safety standards for LNG station installation

Safety standards related to LNG (Liquid Natural Gas) station installation are set to ensure safety during the operation and are used of liquefied gas. Below are some safety standards commonly applied to LNG stations.

- NFPA 59A: National Fire Protection Association (NFPA) LNG Station Safety Standard: This standard identifies basic safety requirements for the design, installation, and operation of LNG stations. It covers every aspect from the storage of LNG to its transportation and use.

- ANSI/API RP 625: LNG Safety Practices Standard of the Petroleum and Gas Standards Institute (API): This standard focuses on regulations and guidelines for safety practices in the LNG sector, including including the installation and operation of the LNG station.

- ISO 16904:2015: Petrochemical Standards Organization (ISO) International Standard for LNG Terminals: This standard provides guidance on the technical and safety requirements for the design, construction and operation of LNG station.

- National Standards: In addition to international standards, many countries have their own standards for LNG station installation and operation. For example, in the United States, the NFPA 59A standard is commonly applied.

- Other regulations: In addition to national and international standards, regulations and standards on safety and environmental protection of the locality where the LNG station is installed also need to be complied with. This includes regulations on safe distances, risk management, and environmental protection.

Every LNG station needs to comply with these standards to ensure the safety of both employees and the surrounding community. This includes building safe facilities, ensuring security, and implementing safety measures during operations.

SEE MORE:

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

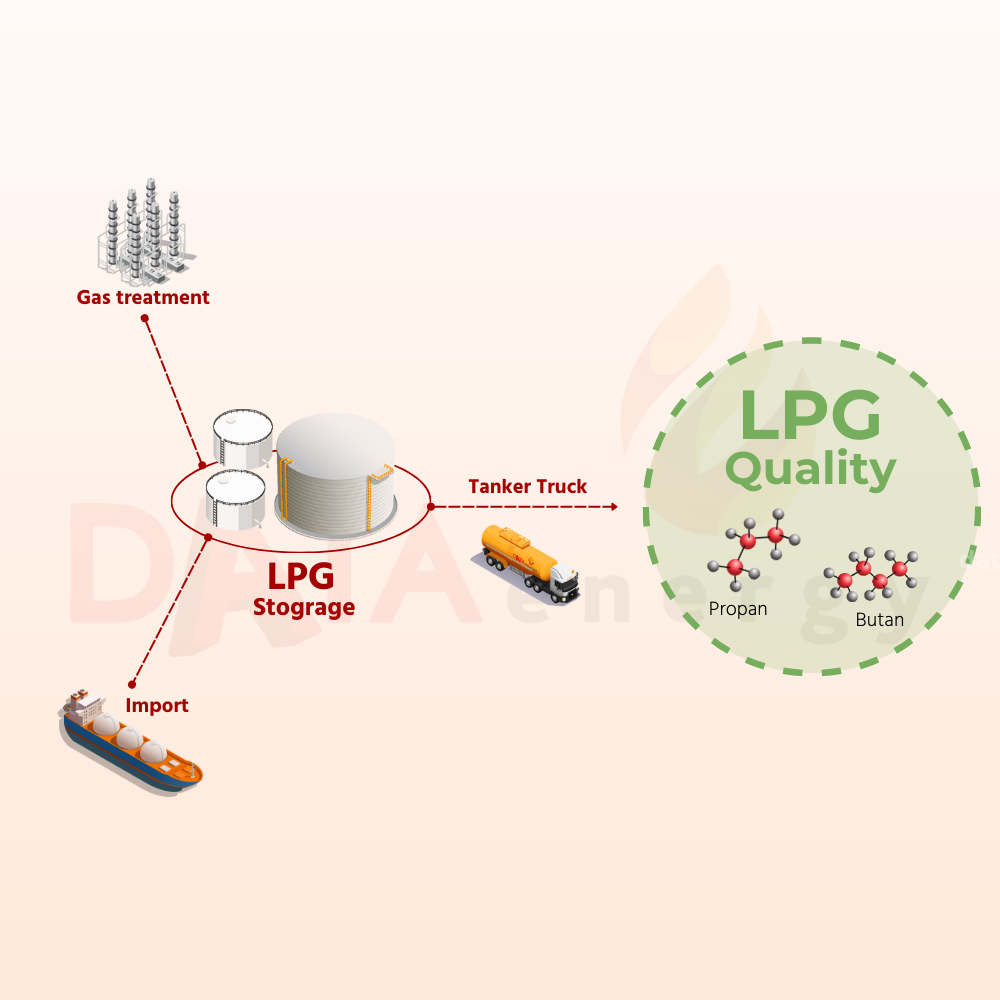

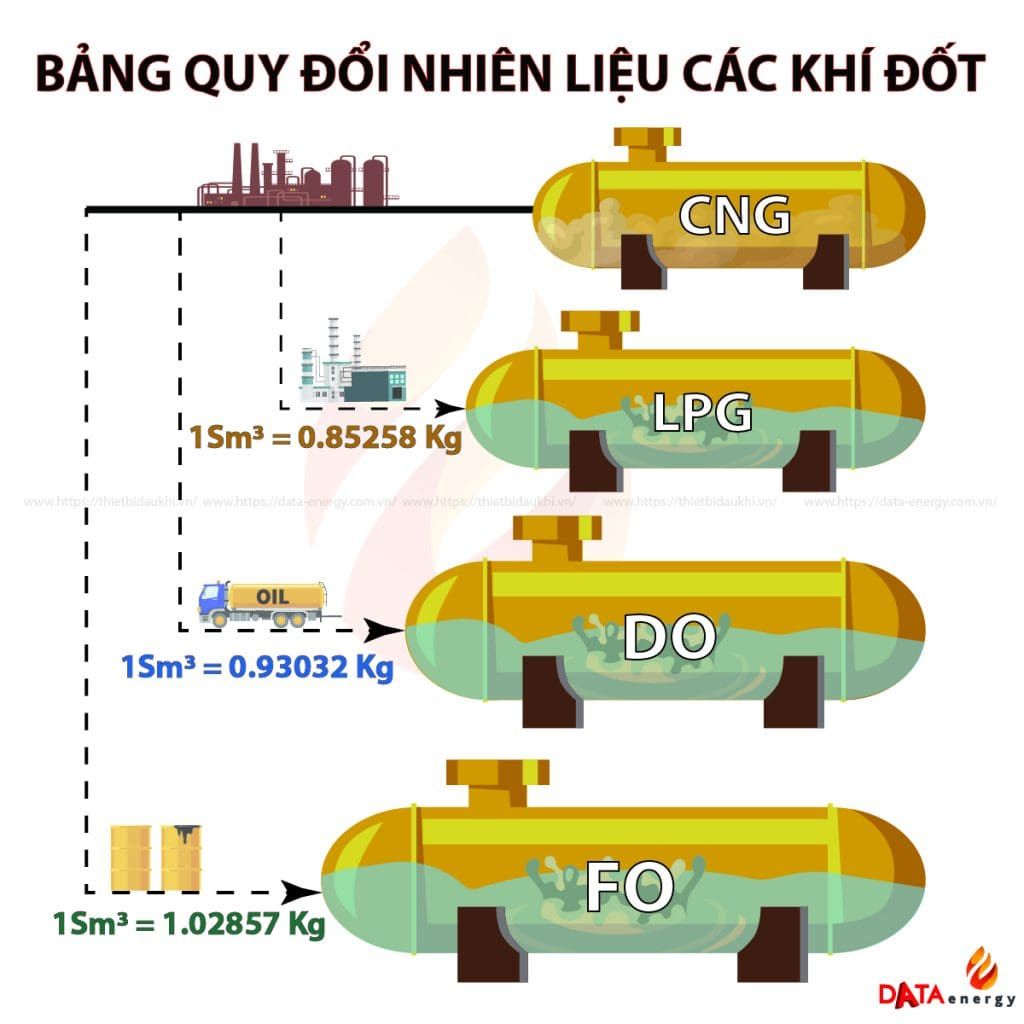

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.