LPG INDUSTRIAL GAS SYSTEM INSTALLATION PROCESS

27/10/2025

DATA Energy - A national provider of investment, consulting, design, and installation services for industrial LPG gas systems. Learn about the construction process for gas stations in the article below.

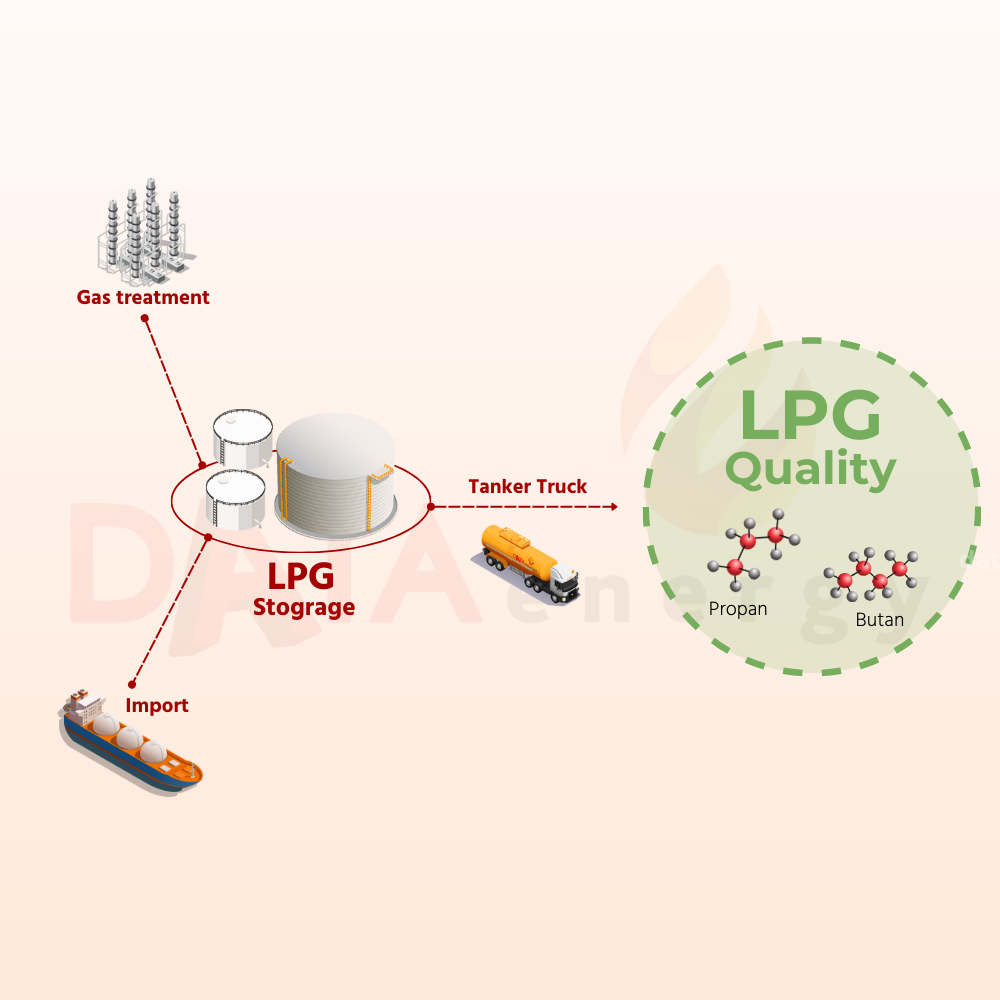

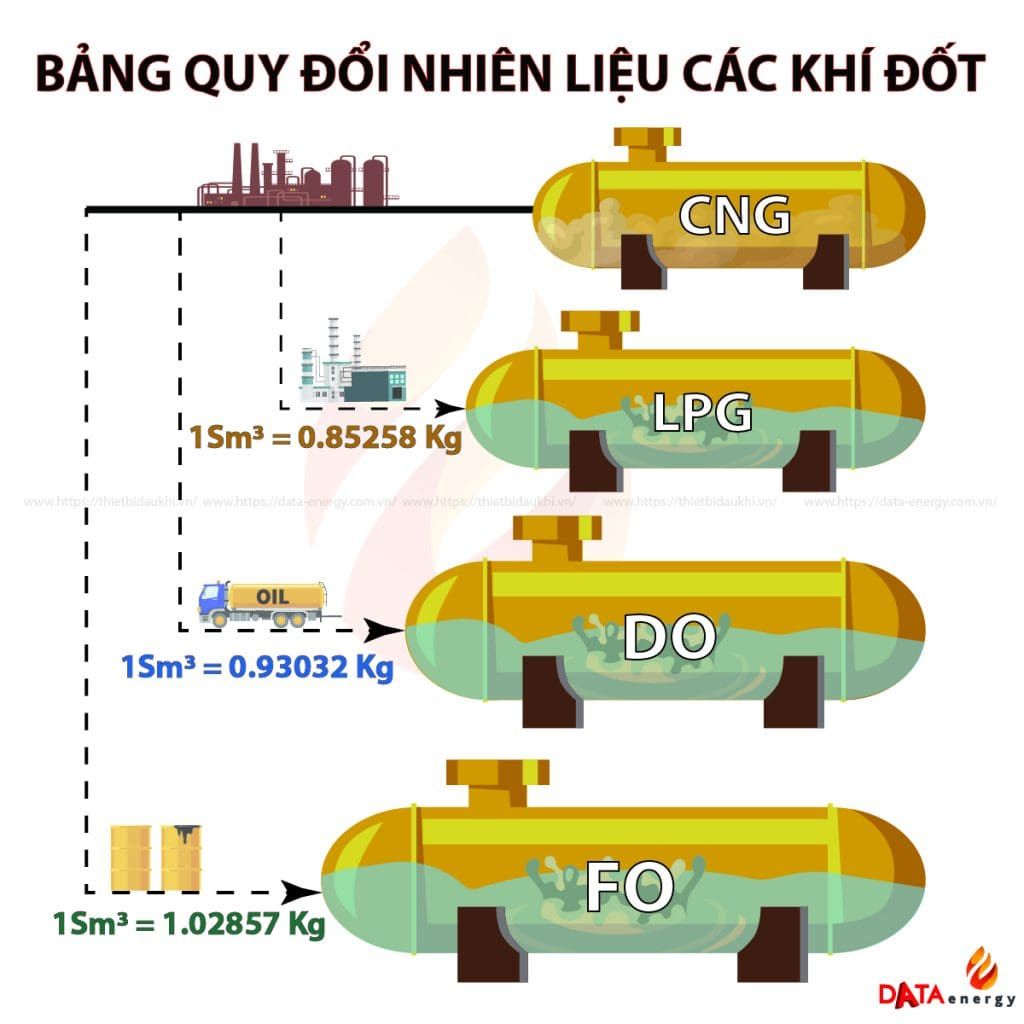

What is LPG? LPG stands for liquid petroleum gas, also known as liquefied petroleum gas. LPG is a mixture of hydrocarbon gases, primarily propane (C3H8) and butane (C4H10) in a 50/50 ratio. This mixture is compressed into a liquid state for storage under a certain pressure.

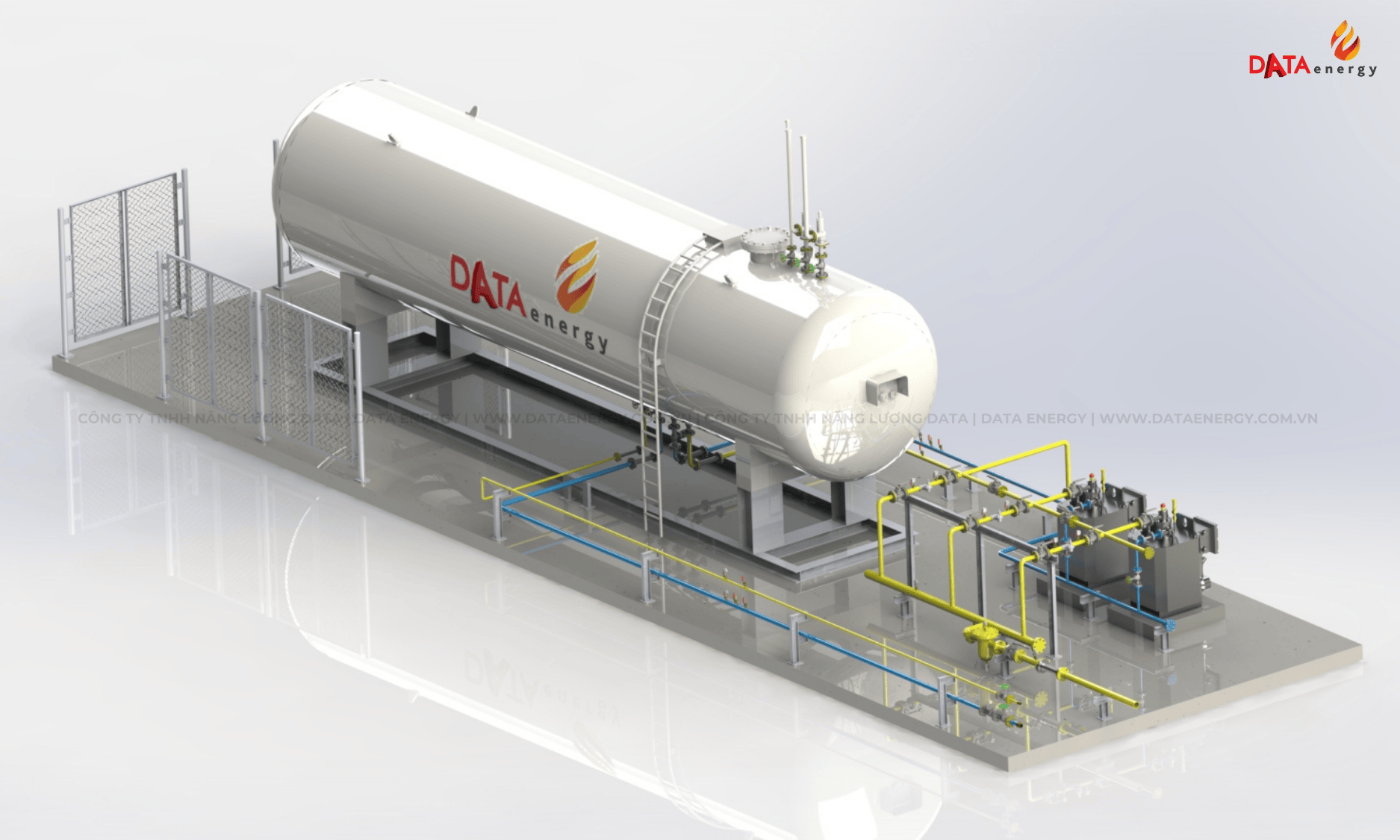

What is an industrial gas system (LPG station)? An LPG station is a station that uses specialized vehicles and equipment to supply LPG from fixed tanks or LPG cylinder systems directly through LPG vapor pipelines to the point of use.

An industrial gas system is understood as a specialized LPG equipment system that functions to store and convert LPG from liquid to gas, then deliver it to the burner for production use.

Currently, we often see industrial gas systems in two forms:

1. LPG cylinder system, usually installed simpler as two clusters of 45kg LPG cylinders.

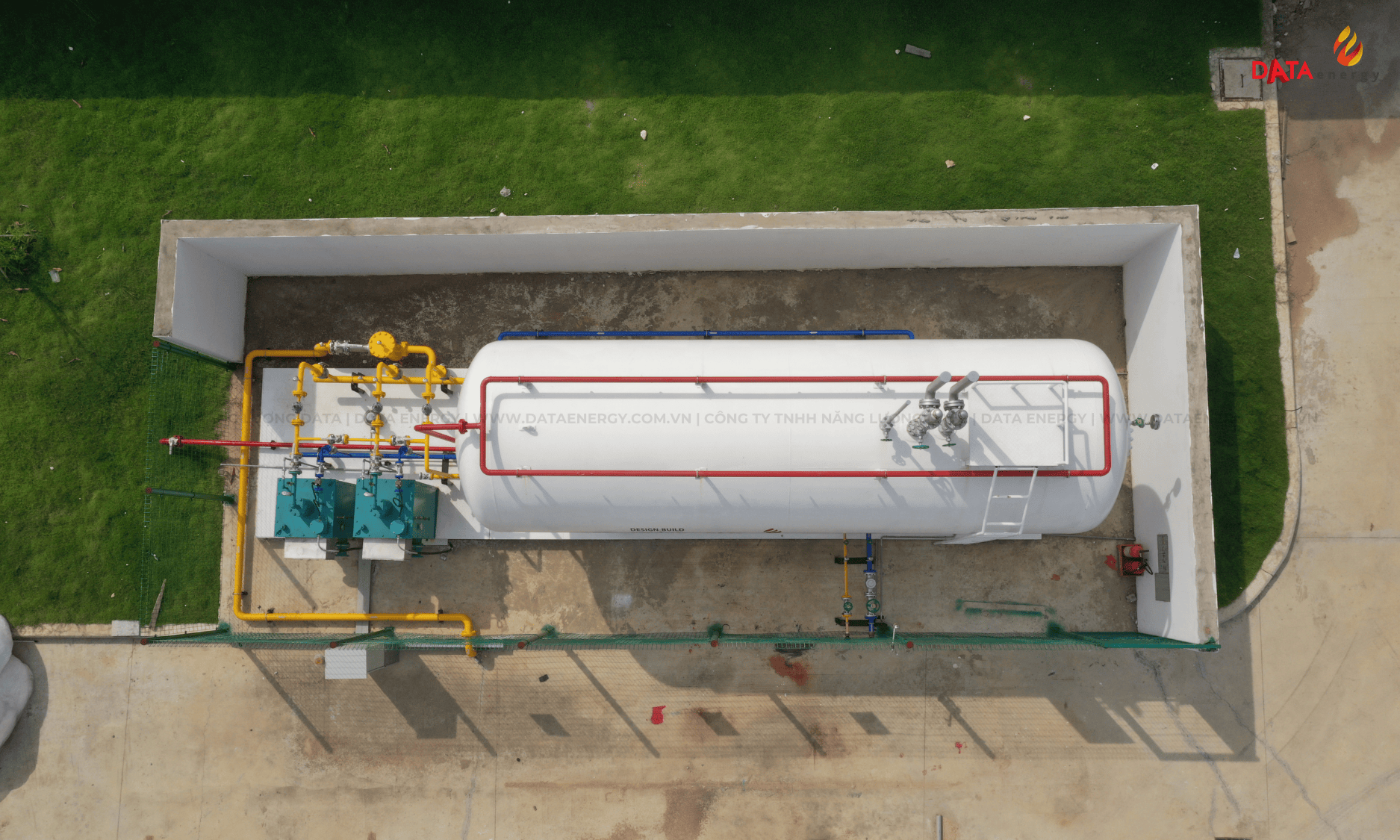

2. LPG stations with tank type, integrating auxiliary equipment, have capacities ranging from 10 to 25 tons, and even multi-tank systems up to 100 tons.

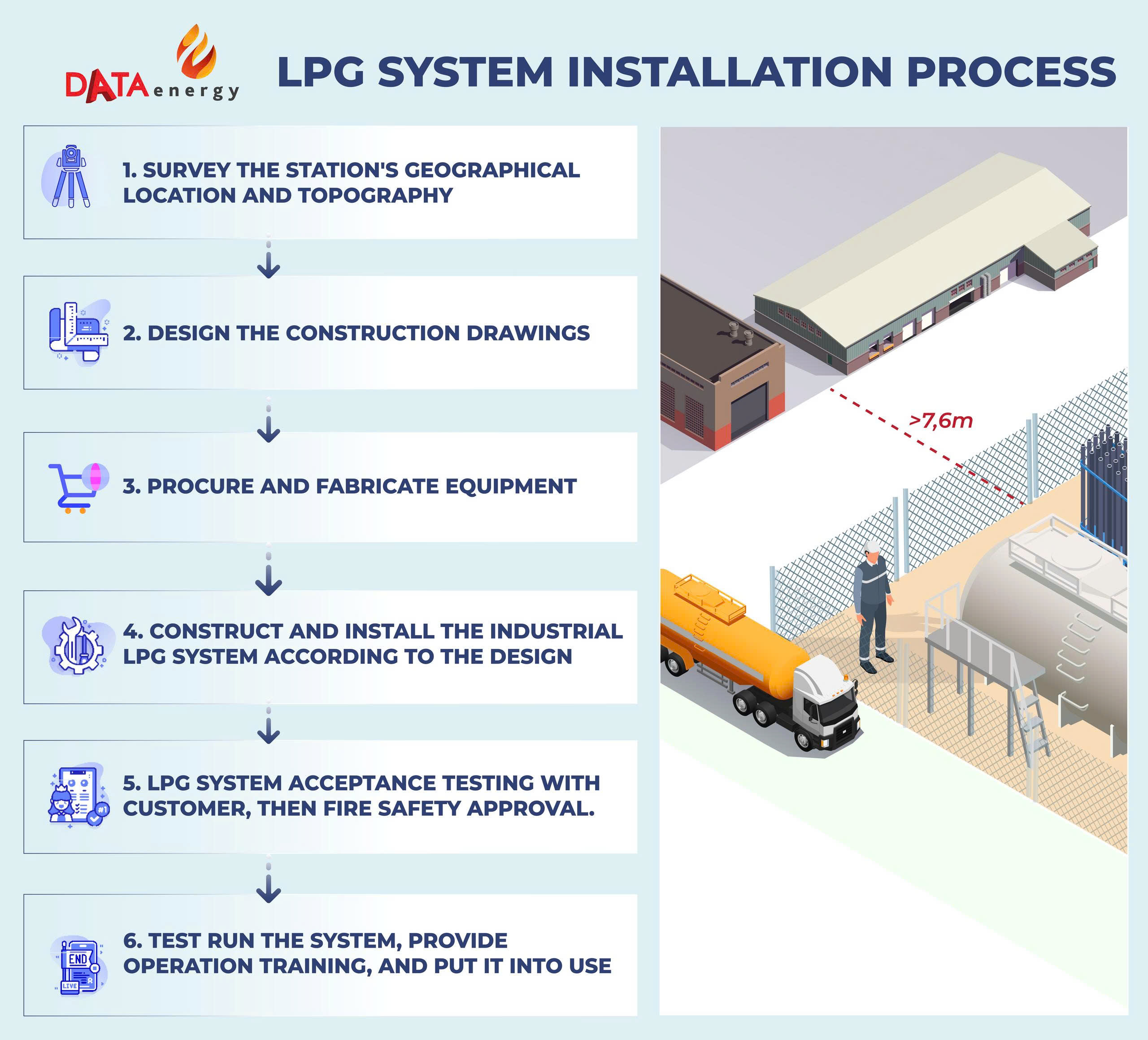

INDUSTRIAL LPG SYSTEM INSTALLATION PROCESS

1. Site Survey:

- Measure the minimum area required for the industrial gas system: (e.g., for a system with a capacity of 200kg/h and a 10MT tank, the customer needs a minimum area of 10m x 5m).

- Ensure safe distances from the LPG station to production areas and comply with other safety standards. Refer to TCVN 7441:2004 standard.

- Ensure sufficient space for LPG tanker movement and liquid LPG loading. Refer to the tanker replacement process.

- Determine the location of the burner/boiler and the piping installation plan to that point. (bridge piping, underground piping, or trench piping options)

- Determine the grounding, lightning protection, electricity, water, etc. plans.

2. Construction Drawing Design:

- Calculate the capacity of the industrial LPG gas system based on the production plan and the capacity of the burner/boiler.

- Design the layout of the station, equipment, and pipelines. (Design documents include: Schematic diagram, station layout drawing, station layout drawing within the overall factory layout, 3D drawing, Shop Drawing, electrical wiring diagram).

- The design drawings must be reviewed by the Fire Prevention and Control Department before construction. (According to Decree 105/2025/ND-CP, it is changed to submitting Fire Prevention and Fighting Assessment Documents)

- Develop a project schedule in parallel with the design process.

3. Equipment Procurement and Fabrication:

- Imported equipment requires a shipping time of 6 - 8 weeks.

- The main equipment group, such as LPG tanks, vaporizers, and pipelines, also requires fabrication time at the workshop if not imported.

4. Construction and Installation of Industrial Gas (LPG) System according to Design Drawings:

- Installation of the industrial gas system according to the drawings, completing the connection to the burner/boiler for production. The installation process takes 2 - 4 weeks.

System and equipment inspection by a third-party entity.

5. Completion acceptance of the industrial gas (LPG) system installation with the customer, followed by fire safety acceptance.

- Completion acceptance of the CNG system installation with the customer/investor in writing.

- Submit documents and invite the competent authority for fire safety acceptance.

This authority will issue a fire safety acceptance certificate for this system (may or may not be included with the fire safety acceptance certificate for the entire factory). (According to Decree 105/2025/ND-CP, it is changed to Fire Safety Inspection Record)

6. System Testing, Operation Guidance and Commissioning

- Industrial LPG gas systems do not require 24/7 operation personnel like CNG systems.

DATA Energy will provide operation guidance to the customer's technical staff to ensure safe and continuous system operation, as well as monitoring of indicators and fault signals.

- DATA Energy conducts maintenance of industrial LPG gas systems every 3 months and provides 24/7 support for troubleshooting.

Other:

DATA Energy is a comprehensive gas solution provider for customers, including: Investment, design, installation and operation of industrial LPG, CNG and LNG gas systems.

See more DATA introduction video.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.