SAFETY PRECAUTIONS WHEN USING LNG

08/01/2025

Known for its efficient and environmentally friendly energy supply, LNG is becoming increasingly important in the national energy structure of many countries, including Vietnam. However, the extraction, transportation, and use of this type of gas pose many risks if it leaks. Let's refer to the content below to learn about the common risks associated with LNG leaks and safety measures to mitigate those risks.

What is LNG?

LNG (short for Liquefied Natural Gas) is liquefied natural gas, primarily composed of CH4 - methane (accounting for about 95% of the total composition).

LNG is colorless, odorless, and non-toxic. It is cooled to -162ºC to transition into a liquid state.

Risks of LNG Leakage

1. Fire and Explosion Risk

LNG is a flammable gas. When leaked, LNG quickly vaporizes and forms methane gas in the air. If oxygen and a heat source are present, it can ignite and explode when the concentration of natural gas in the air is 5-15%. If exposed to a flame or spark, this methane gas can cause a major fire or explosion.

2. Suffocation Risk

Natural gas is a suffocating gas in enclosed spaces (Normal oxygen content in air is 20.9% by volume. An environment containing less than 18% oxygen is likely to cause suffocation). In the event of LNG leakage, the vaporized gas can displace oxygen in the air, causing suffocation, nausea, or dizziness due to reduced blood oxygen levels.

3. Environmental Impact

When LNG leaks and vaporizes, methane (CH4) is released into the air, contributing to global warming as methane is a potent greenhouse gas, emitting 80 times more greenhouse gases than carbon dioxide (CO2).

4. Impact on Human Health, Especially Cold Burns

LNG is a gas that is cooled to a very low temperature (-162°C), which can have a significant impact on body parts that come into contact with it. Leaking LNG can cause cold burns; sensitive tissues like the eyes can be damaged by contact with this cold gas, even for very short periods, without affecting the skin on the face and hands.

Furthermore, body parts not equipped with protective gear should not be allowed to touch uninsulated LNG pipelines or tanks. Extremely cold metal components can stick to the skin and can tear the skin when attempting to remove them.

LNG Safety Measures

1. Strict Safety Practices for LNG Systems:

* Design, construction, and maintenance must adhere to strict safety standards as mandated by law.

* The system must include warning devices, safety valves, emergency shutdown systems, and alarm devices to detect gas leaks.

* Follow proper maintenance procedures for the system and related equipment.

* Repair or replace damaged or deteriorated equipment to ensure safety.

* Improve ventilation systems for rapid gas evacuation in case of leaks.

* Materials for cooling and heating water supply systems (for ambient heat vaporizers) must meet corrosion and abrasion resistance requirements.

* Protective barriers, security controls, and hazard zone signs should restrict unauthorized access to the LNG plant.

* Equip the LNG operation area with "No Fire, No Smoking" signs, fire extinguishers, and emergency exits for prompt emergency response.

2. Training and Safety Guidance for Personnel:

* All operating and technical personnel must receive thorough training on safe LNG procedures and emergency handling.

* Regular drills should be conducted to prepare personnel for incidents.

* Protective clothing, gas masks, and gloves are mandatory for all personnel working at the LNG plant.

* Close monitoring and control of the LNG usage process, from personnel to equipment and machinery, is essential.

References:

* TCVN 8610:2010, Liquefied Natural Gas (LNG) - Equipment and Installation Systems - General Properties of LNG.

* TCVN 8614:2010, Liquefied Natural Gas (LNG) - Equipment and Installation Systems - Testing the Compatibility of Gaskets Designed for Flanged Connections on LNG Pipelines.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

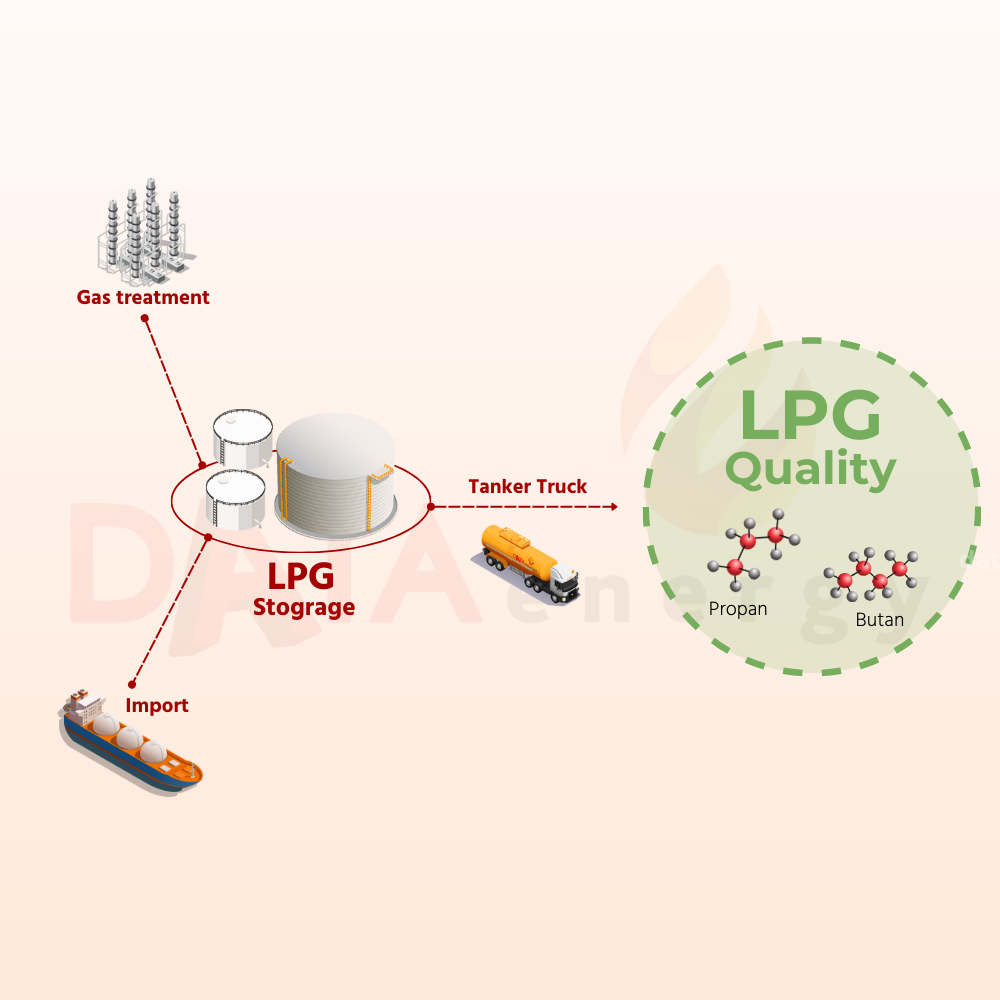

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.