UNDERGROUND LPG TANK

13/11/2024

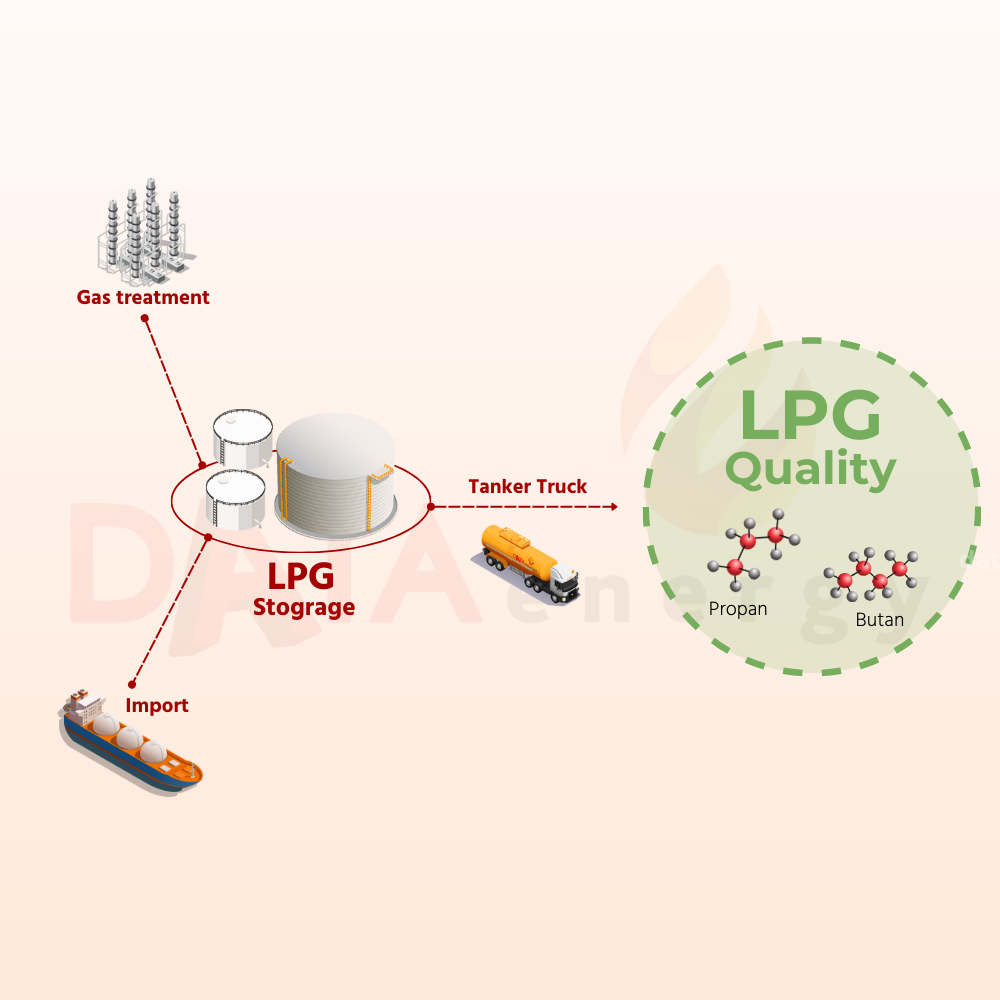

LPG tank (industrial gas tank) is a specialized device to store LPG (Liquefied Petroleum Gas) for production and business activities. There are 2 forms of mounting LPG tanks: floating tanks on the ground or underground tanks. In the article below, we will learn about the advantages and disadvatages of underground LPG tanks and how to install this kind of tanks.

Advantages:

- Save space: Built-in LPG tanks are placed underground, do not take up floor space, and are aesthetically more beautiful than floating tanks.

- Optimized in terms of safe distance according to fire protection standards

- Protects the tank from environmental impacts: Limiting the tank's oxidation resistance, installing a recessed tank will also help the tank not be affected by environmental temperature.

Disadvantages:

- Installation cost: Installing an underground LPG tank will cost more than installing a floating LPG tank due to the requirement of excavating soil, pouring concrete to contain the gas tank, installing gas pipes and lowering the tank. The soil is very difficult (must strengthen the sink to avoid floating and requires high precision). In addition, the cost of constructing the tank is also quite high because it must be equipped with an anti-corrosion layer for the tank.

- Difficulty in maintaining and checking the underground tank body: Checking and maintaining acoustic gas tanks is quite more difficult than floating gas tanks due to having to dig the ground to access.

- Risk of gas leaks being difficult to detect: If there is a gas leak from a concealed tank, detecting and troubleshooting the problem may become more difficult than with a floating gas tank.

- In addition, when customers want to renovate or move the system, it is more difficult to handle than a floating tank and the cost is also quite high.

- When carrying out construction and installation, the construction unit needs to have accurate calculations and techniques to ensure that the geological composition meets the requirements, limiting noise to avoid problems related to structure and safety system.

INSTALLATION PROCESS OF UNDERGROUND LPG TANK

- Survey the geographical location and topography of the station installation.

- Construction drawing design.

- Dig an underground hole to accommodate the tank according to the dimensions on the drawing.

- Construction of the underground LPG station foundation and fence (concrete) system.

- Install LPG tank. After completing the foundation and fence, the LPG tank will be transported and craned into the dug hole. The process of putting the tank into the soil hole must ensure safety measures to ensure correct placement of the tank and limit other risks.

- Fabrication and installation of valve systems, pipes, tank reinforcement.

- Build the station foundation above.

- Install pipes, racks and other equipment at the station.

- Acceptance of installation with the investor and then acceptance of fire protection.

- Test run, acceptance completed and handed over to the Investor, the system went into operation.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.