WHAT IS LPG VAPORIZER? THINGS YOU NEED TO KNOW ABOUT LPG VAPORIZER

06/01/2025

What is LPG Vaporizer?

A vaporizer (or vaporizer) is a device that provides heat during the LPG (liquid phase) vaporization process after it is transferred into LPG (gaseous phase).

Why is a vaporizer needed?

Overall, for factories that require large and continuous gas consumption, vaporizers are essential for optimizing production processes, ensuring product quality and output. Large capacity can range from 100kg of output per hour and typically operates for 4-8 hours continuously. Moreover, the process of converting LPG from liquid to gas involves many risks, so vaporizers are needed to ensure a safer conversion process and stable output.

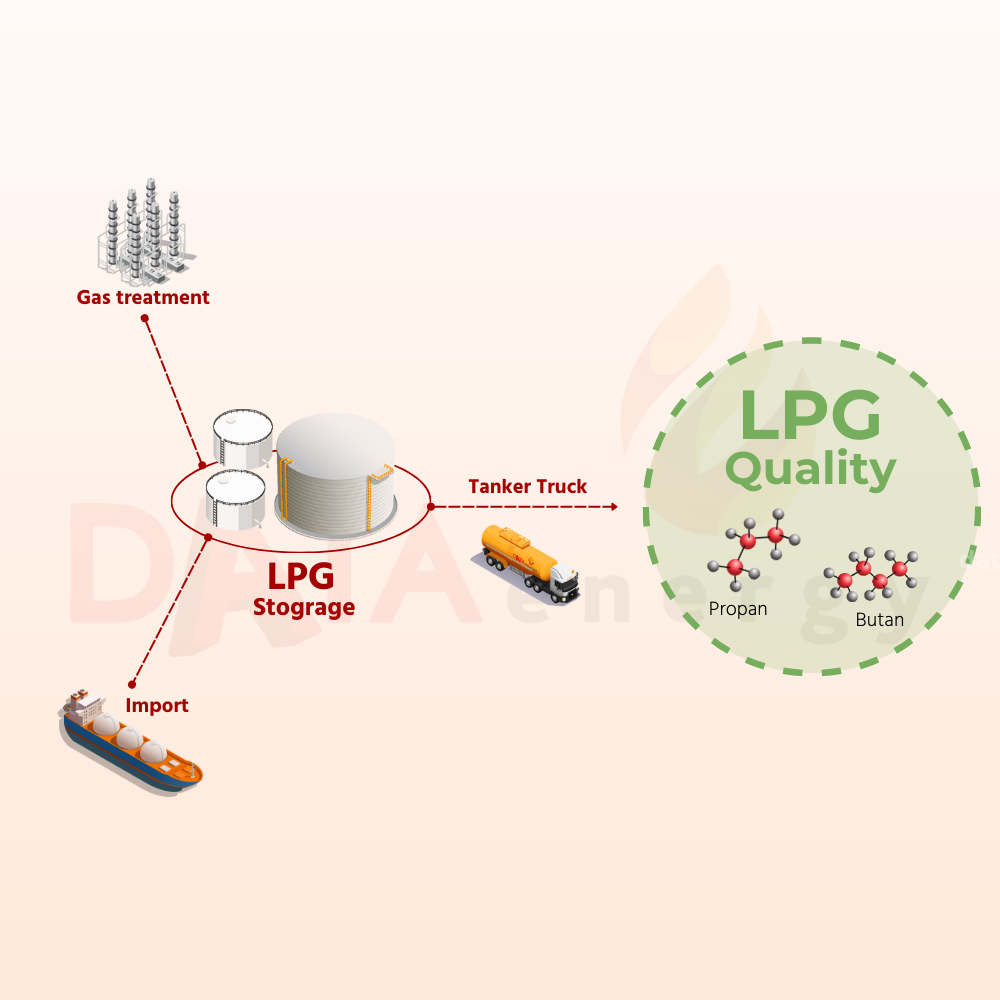

LPG storage tanks contain two main gases: Propan (C4) and Butan (C3). The vapor pressure of C3 is higher than C4, making it easier to evaporate first. The escape of C3 from the tank will lead to a decrease in internal pressure and an unstable flow rate.

Natural vaporization occurs when the ambient temperature reaches a certain level. When the ambient temperature changes, the vaporization rate will become saturated. Therefore, a device is needed to force LPG vaporization, such as a vaporizer, to ensure that saturation does not occur when the ambient temperature changes.

Structure of LPG Vaporizer

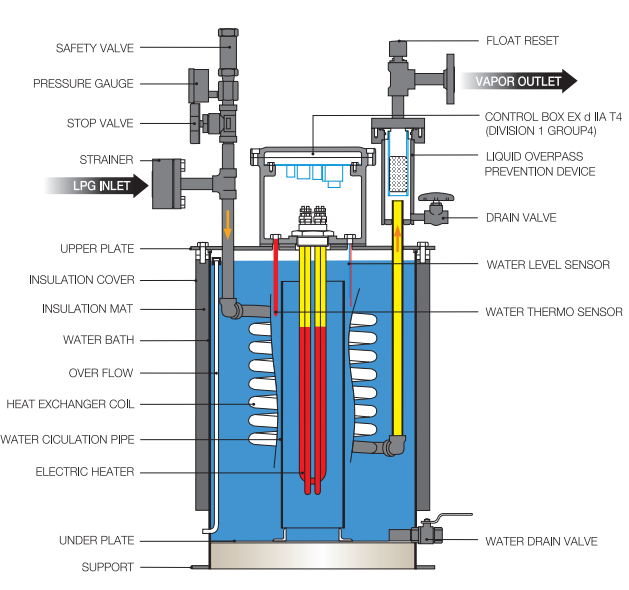

The common vaporizer is designed for indirect heat transfer through water. The heating system in the tank is responsible for vaporizing the liquid LPG and regulating the water temperature. The main components of the vaporizer include:

- Liquid LPG and vapor line shut-off valve

- Safety valve directly connected to the LPG vapor space. The safety valve must be a direct compression spring type or equivalent, non-adjustable and designed so that in the event of any component failure, it cannot affect the pressure relief function of the valve.

- Emergency shut-off valve at the inlet of the vaporizer must be installed in a location that is easy to operate, visible and easily accessible in an emergency.

- Automatic control valve. For vaporizers, it is mandatory to choose a suitable automatic control valve to prevent LPG from overflowing into the pipeline and vapor LPG pipeline space.

- Level gauge, water level indicator

- Pressure gauge at the outlet of the vaporizer

- Temperature indicator

The operating principle of a vaporizer.

Liquid petroleum gas (LPG) will be drawn from the storage tank or transfer tank through the liquid line into the vaporizer. Here, the vaporizer is a heat exchanger, where the LPG is heated by the burner that boils water in direct contact inside the machine (water temperature 60-65°C). Through the coiled tube, the LPG is forced to vaporize into a gaseous state and transferred to the gas line of the vaporizer.

Why choose to use vaporizers at DATA Energy?

- Our team is well-trained, experienced in the field, enthusiastic, attentive, and dedicated.

- We guarantee the quality and origin of all equipment and machinery.

- Competitive pricing compared to the market. At DATA Energy, we always provide the best solutions at reasonable and competitive prices.

- We are committed to ensuring safety in design, installation, and construction.

- Fast and timely warranty and repair processes.

-min.png)

-min.png)

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.