Inspection of industrial LPG systems is mandatory.

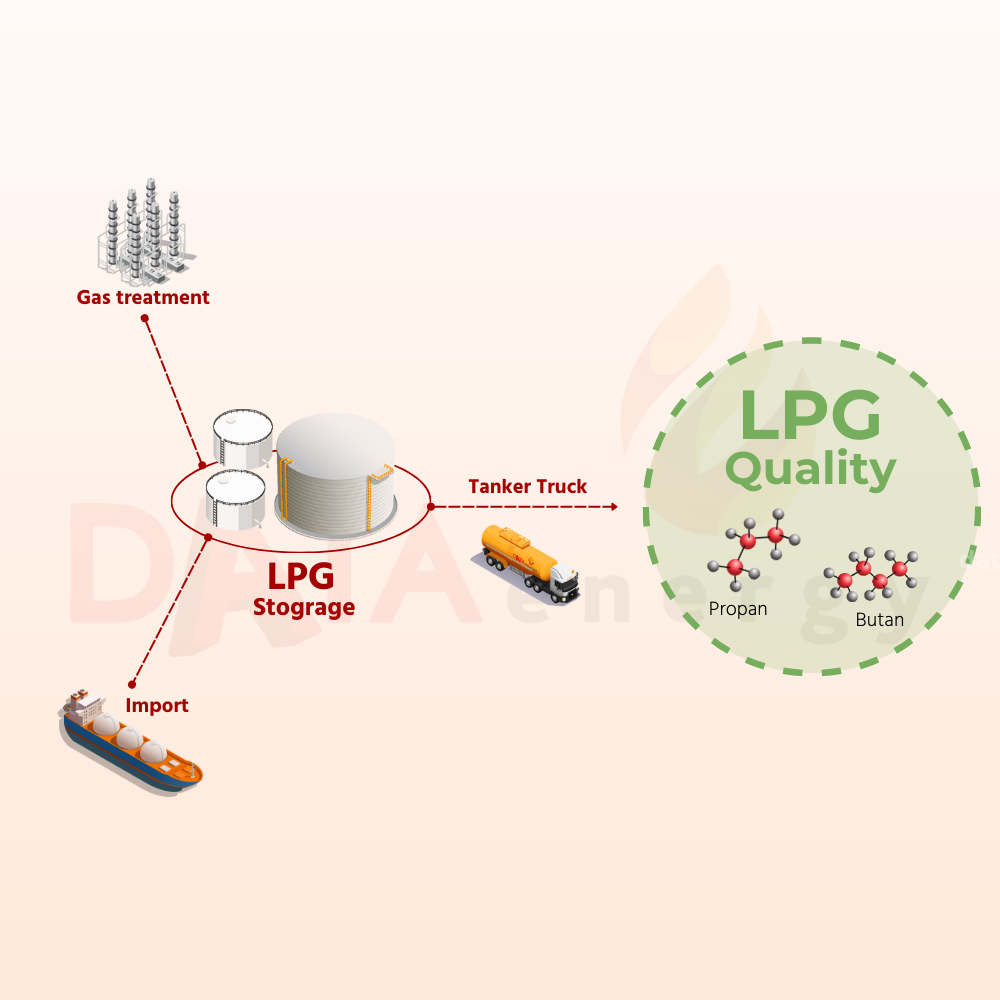

26/12/2025Industrial LPG system inspection is the process of checking, evaluating, and certifying the technical safety level of the entire system using liquefied petroleum gas (LPG) in industrial production. This system includes the storage system (gas tanks), vaporization system, pressure regulator, gas pipelines, and related safety equipment.

The inspection is carried out by a third-party unit authorized to conduct technical safety inspections according to legal regulations.

Why is industrial LPG system inspection necessary?

LPG is a high-pressure fuel and poses a potential fire and explosion risk if leaks occur. In an industrial production environment, LPG system inspection helps businesses:

• Ensure safe, stable, and continuous operation;

• Early detection of technical risks in the system and production line;

• Compliance with legal regulations and requirements of regulatory agencies;

• Minimize the risk of accidents and human casualties.

Inspection is not just a formality but a mandatory risk prevention measure.

Items in industrial LPG systems requiring inspection:

• LPG storage area (tanks or cylinder clusters)

• LPG vaporization system

• Pressure regulator and safety equipment

• LPG pipeline system

• Valves, pressure gauges, emergency shut-off devices

• Grounding and anti-static systems

.jpg)

Inspection schedule and cycle for industrial LPG systems

Inspection of industrial LPG systems is carried out throughout the operational lifecycle, including the following key milestones:

1. Initial inspection

Performed after installation is complete and before the LPG system is put into use.

The purpose is to confirm that the system was constructed according to design, meeting technical and safety requirements. This is a mandatory condition for the system to be allowed to operate officially.

2. Periodic Inspections

Periodic inspections are performed periodically for each item in the system. Common reference times are as follows:

|

|

LPG Tank |

Safety Valve |

Vaporizer |

Pipeline and Pressure Reduce Vavle |

Meter |

|

Second inspection |

After 3 years |

After 1 year |

After 2 years |

After 3 years |

After 1 year |

|

Subsequent inspection |

yearly |

yearly |

yearly |

yearly |

yearly |

The specific cycle may be adjusted according to the requirements of the regulatory authority or actual operating conditions.

3. Abnormal Inspection

Abnormal inspections are performed when:

• The LPG system undergoes major repairs, renovations, or relocation.

• There are changes in system capacity or configuration.

• Abnormal signs are detected, such as leaks, voltage drops, or safety equipment failures.

• There is a request from the relevant authority or insurance company.

Timely inspections help prevent incidents and ensure the system does not operate in an unsafe condition.

Conclusion

Inspection of industrial LPG systems is a mandatory requirement to ensure safety, legal compliance, and stable production operations. Performing inspections on time for each item helps businesses proactively control risks and improve the reliability of their energy systems.

Contact us: (028) 62 757 005 or Ms. Oanh – 0985 142 050 for consultation and quotation.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

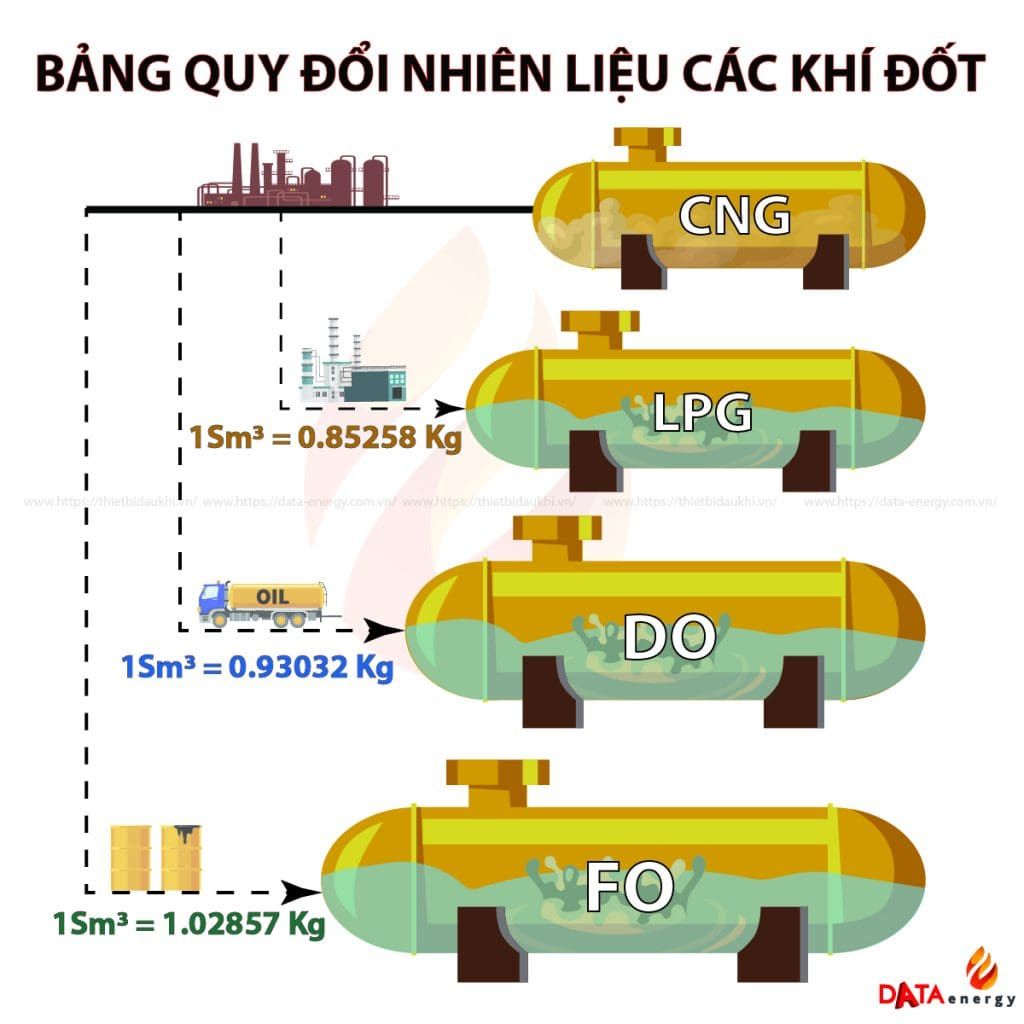

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.

More Information: