LNG IN INDUSTRIAL PRODUCTION

03/01/2025

One of the common applications of liquefied natural gas (LNG) is as fuel for processing in industrial production activities such as heating, drying, burning, etc. Although this is a relatively new type of fuel and is not yet widely used in Vietnam, liquefied natural gas (LNG) is predicted to be a future fuel source in the industrial manufacturing sector due to its advantages.

ADVANTAGES OF USING LNG IN INDUSTRIAL PRODUCTION

* ENVIRONMENTALLY FRIENDLY

Liquefied Natural Gas (LNG) is one of the most environmentally friendly fuels available today. The combustion process of LNG emits less CO2, NOx, and SO2 (estimates suggest that using LNG as fuel reduces CO2 emissions by up to 25%, NOx by about 90%, and SO2 by 98%, along with fine dust). Additionally, LNG evaporates faster than oil and traditional heavy fuels when exposed to air, therefore it leaves no residue on water or land.

* MINIMAL SURFACE IMPACT

Due to the complete combustion process, which does not cause residue buildup in the combustion equipment and fuel mixing systems of vehicles, LNG helps improve efficiency, extend maintenance cycles, and increase the lifespan of machinery and equipment for businesses.

* SAFETY

Safety is one of the top priorities in the industrial gas industry in general and for Liquefied Natural Gas (LNG) in particular. LNG is less likely to ignite spontaneously on a hot surface because it has a high auto-ignition temperature and a narrow flammability range (5% - 15%). This means that if the concentration of LNG in the air is below 5% or above 15%, it will not burn. This high ignition temperature and limited flammability range make spontaneous ignition or accidental combustion very unlikely.

* EFFICIENCY OF USE

Liquefied Natural Gas (LNG) is natural gas compressed at high pressure (over 230 bar), which reduces the storage volume, increases efficiency of use, and ensures complete combustion.

* EASY TRANSPORTATION

Liquefied Natural Gas (LNG) reduces the volume by 600 times compared to natural gas (NG), allowing LNG to be transported safely and economically by ship from the source to onshore storage facilities in large quantities.

* NATURAL GAS IS A TREND MATERIAL OF THE FUTURE

Amidst significant efforts by the gas industry to reduce greenhouse gas emissions, the use of natural gas in production is becoming a global trend.

in industrial production.png)

LNG SUPPLY PROCESS IN INDUSTRIAL PRODUCTION

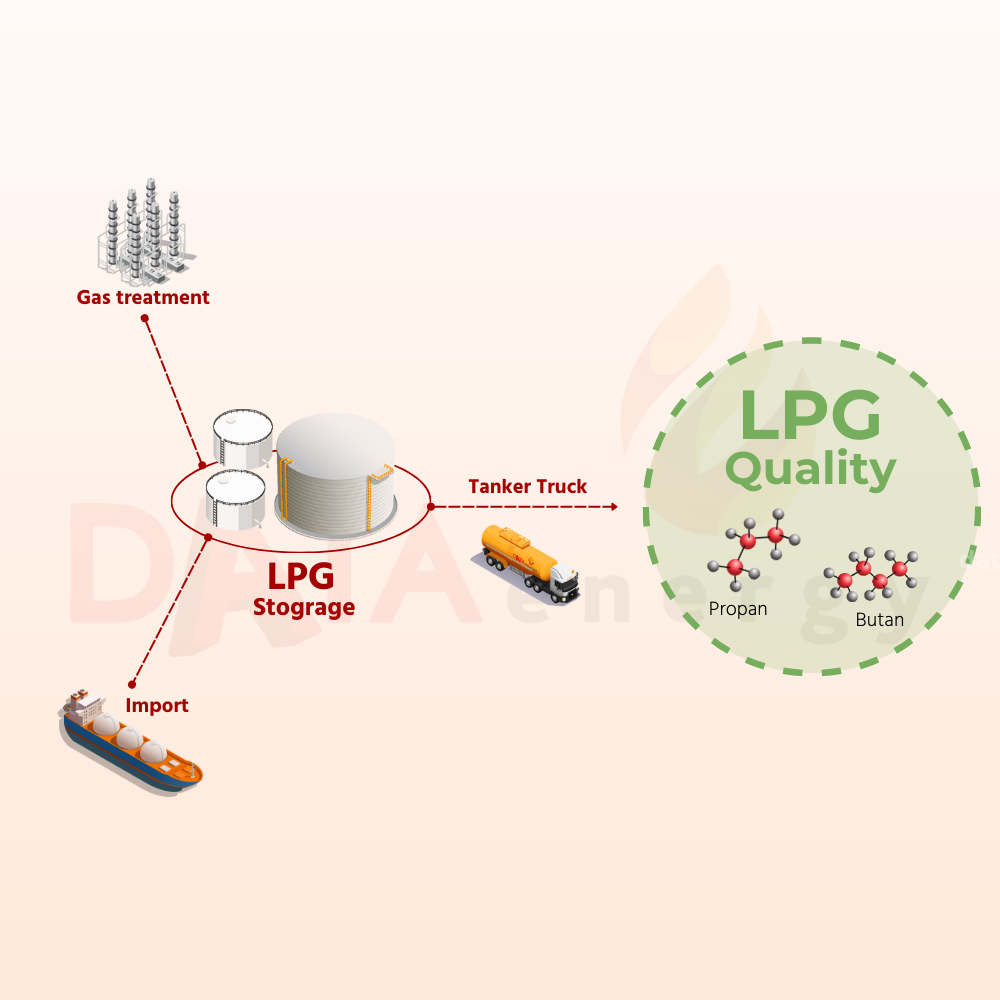

After receiving the goods, liquefied natural gas (LNG) has two ways to be transported to the end user.

LNG is transported by tank trucks to the customer's factory. Then they are directly loaded into storage tanks at the factory and then go through the gasification system to produce. (Similar to LPG transportation)

LNG is transported by specialized tank trucks, which are both the means of transport and the LNG storage tank. At this time, the factory only needs to install an LNG vaporization system to produce. (Similar to CNG transportation).

Depending on the customer's needs, a regasification system can be installed, including an LNG storage tank and regasification equipment to convert LNG back to natural gas for customer use.

![]()

DATA ENERGY COMPANY LIMITED (DATA Energy)

- Supply LPG, CNG, LNG.

- Consult, Design, Install Industrial Gas System.

- Invest Gas System (LPG, CNG, LNG) for the factory.